Rapid Molding Process makes medical components.

ZA-12 casting process uses permanent graphite molds to produce parts from ZA-12 zinc-aluminum alloy. Castings can include contours, surface elevations, holes, and other precise features. Process is suitable for making high-precision components for medical equipment and is economical in quantities of 300 to 20,000 parts per year. Company provides design, rapid prototyping, tooling and mold...

Read More »

Drilling System drills deep holes fast.

Model 200 BTA system has drilling capacity of 2.5 in. dia and 84 in. effective drilling depth. It is equipped with special refrigeration for proper coolant temperature control. Counter-rotation of workpiece helps system attain close tolerances. System drills nickel-base Inconel 600 and 700 series workpieces at penetration rate of 1.5 in./min.

Read More »

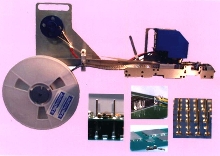

Feeder streamlines SMT pin placement on multiple platforms.

AutoFeeder(TM) supports placement of SMT pins and other interconnects on existing pick-and-place equipment. Primary transport mechanisms and component handling functions are matched directly to existing feeder mounting methodology used by major equipment manufacturers to create seamless interface for each SMT placement platform. AutoFeeder handles continuously reeled components including...

Read More »

Thermoplastic Seals handle high temperatures.

UltraCOMP(TM) engineered thermoplastics are resistant to creep and fatigue in temperatures up to 500 deg F. Chemical, electrical-, and radiation-resistant seals can operate continuously and be regularly sterilized by steam, as common with medical device seals. Material is available in 4 formulations: virgin, carbon fiber-filled, glass-filled, and carbon/graphite/PTFE-filled. Tube sizes are up to...

Read More »

A Guide to the Non-Metallic Precision Stamping Process

This white paper provides a guide to the non-Metallic precision stamping process.

Read More »

Castings reduce road renovation time.

Final Cut castings eliminate need for pavement removal around street castings. Cover and rim elevation of manholes, catch basins, and hand holes can be raised by 1 1/2 in., regardless of thickness of cover. Cast iron construction provides corrosion resistance and durability. Combination of Final Cut rim, riser and cover allows use of BMPs for control of erosion and sedimentation.

Read More »

Intermediate Bulk Container resists bulging without steel.

OTP-All-Plastic IBC can be used for shipping and storage of heavy products with specific gravity ratings up to 1.6, such as adhesives, sauces, gravies, paints, and coatings. Supported by reinforcing ribs, IBC resists bulging and ensures structural integrity without requiring steel frames or cages. Rotomolded of LLDPE, it accommodates 4-way lift access, stacks 2 high when full and 3 high when...

Read More »

Abrasive Belt Machine has thermally insulated housing.

Dynafile portable, air-powered machine grinds, deburrs, blends and finishes normally inaccessible areas on metal, plastic, fiberglass and other composites. Composite, quick-change housing cover allows for easier contact arm and abrasive belt change. Over 30 different interchangeable contact arms are available. Machine operates at 20,000 rpm, and uses coated abrasive belts 1/2, 1/4, or 1/8 in....

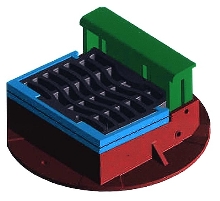

Read More »TEM Systems remove every burr.

TEM (Thermal Energy Method) systems perform internal and external deburring of cast iron, steel, stainless steel, and aluminum parts with intense bursts of heat. They also perform deflashing of die cast zinc parts. Both manual and fully automatic TEM systems are available. Parts are sealed in deburring chamber by 250 ton force, and oxygen/natural gas mixture is introduced. Machine-initiated park...

Read More »

CO2 Laser offers ultra-short, high-peak-power pulses.

DIAMOND(TM) GEM Q-400 Q-switched CO2 laser produces 15W avg power at 50 kHz repetition rate and 9.25 micons wavelength. It features 2.5 kW peak power with pulse widths controllable to less than 150 ns and peak pulse energies to over 400 microjoules. RF-excited waveguide oscillator is sealed in all-metal housing. Laser is designed for drilling and micromachining applications including PCB microvia...

Read More »

Conformal Coatings are environmentally friendly.

UL-listed Series 1H coatings are non-flammable, non-hazardous to handle, and suitable for moist conditions. Water replaces solvents in acrylic and polyurethane coatings. Coatings offer stability, flexibility, and chemical resistance. Optimal performance is reached with thin coatings that can be applied by robotic selective coating systems, to control thickness for maximum economy, or by dipping...

Read More »

Triad WAU Wall Plug-In AC Power Supply May Be First To Meet Level VI Energy Efficiency Standard

Triad Magnetics, an industry leader and one of the most trusted names in transformer design and manufacturing, is proud to announce the release of the Triad WAU Wall Plug-In AC Power Supply. Engineered to provide robust performance and high reliability, it is setting the standard for 120V/60Hz power supplies. See our video to learn all about it.

Read More »