Bright Tin Acid Process suits rack and barrel electroplating.

Based on sulfuric acid electrolyte, Technibrite HT 1000 has low current density bright range, even when plating bath temperature and tin concentration parameters are higher than normal. Process can run without chiller, and will produce bright deposit at low current densities at process temperatures as high as 35Ã-

Read More »Electroless Nickel Plating Service plates converting machinery parts.

Targeting converting machinery industry, medium and high phos electroless nickel plating is available for parts up to 10 ft long. Corrosion-resistant coating may be applied toÃ- winders and unwinds, drive control systems, I-beams and rollers,Ã- large plates, plenums, andÃ- frame components. Converting machinery finishing, conforming to MIL-C-26074, AMS-C-26074, ASTM B733, and AMS 2404...

Read More »

CW Industries Now Provides Economical Barrel and Reel-to-Reel Plating for a Variety of Industries

Southampton, PA. — CW Industries, a long recognized manufacturer of switches, connectors and custom components for the OEM, has created a separate business unit to focus and market itsÃ- In-House Plating capabilities to end users in a variety of industries. CW has unique capabilities and incorporates the latest technologies in delivering both selective Reel-To-Reel and Barrel plated...

Read More »Globe Products Announces New Plating Chemistry, Making Process Much More Efficient

Ennis, Texas – Globe Products, a worldwide leader in manufacturing high quality ferrules and eyelets for the past three decades, has recently made big changes to its plating chemistry formula for bath work, and can now handle its plating faster and more efficiently, with greater control over the procedure. Globe Products implemented an automated barrel zinc plating line, designed by Jessup, in...

Read More »

Mitigating Supply Chain Risks for Sheet Metal Components

This ebook provides an overview into mitigating supply chain risks for sheet metal components.

Read More »

Gold Coating Now Available in Matte or Bright Finish

Epner Technology is a high-tech engineering and specification plating company. It's Laser Gold infrared reflective coating is world renowned and has been the NIST standard for some 20 years. Plating difficult metal substrates such as molybdenum, titanium and beryllium, and the plating of the engineering plastics such as Ultem, Teflon Torlon and Ryton are a specialty of this hundred-year-old...

Read More »

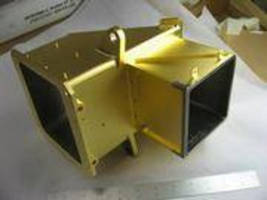

Gold Plating for Space Programs

Epner Technology is a leading plating and coating service. Precious metal plating and gold plating to NIST reflectance standards is Epner's specialty. With over 90 years of electro and electroless plating experience Epner is ISO 9001:2000 and NADCAP certified. Epner showcasing radiation shield for a space based system with a laser gold finish. This large radiation shield started life as a 30'...

Read More »

Laser Gold Plating for IR Reflectance

Epner Technology is a leading plating and coating service. Precious metal plating and gold plating to NIST reflectance standards is Epner's specialty. With over 90 years of electro and electroless plating experience Epner is ISO 9001:2000 and NADCAP certified. Epner now adds to it's plating offerings with a unique process for altering the surface morphology of the substrate to be plated or...

Read More »

New Low-Temp, Black Chrome Plating Offered on Misumi Components

Date: February 20, 2008 Corrosion-resistant, low-reflective coating will not peel or flake Schaumburg, IL-MISUMI USA, Inc. announces the immediate availability of low-temp, black chrome plating on a variety of the company's motion components, including linear shaft, linear bushings, linear guides, ball screws and others. Through electroplating an alloyed surface is formed to create an...

Read More »

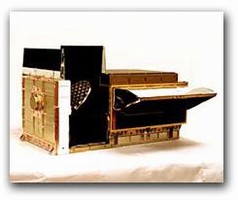

Epner Technology is Chosen by NASA for IR Coating

Epner Technology is a leading coating and plating service announces an advance that provides hard gold electroplating chemically deposited with IR reflectivity over 99%. Hard enough (200+ Knoop) to withstand repeated cleaning, it passes 50 rubs of MIL-M-13508C. Laser gold plating is applied to imaging optics with no distortion of the optical figure and its remarkable low emissivity (.02) makes it...

Read More »

RoHS Compliant Plating Line

Where the finish comes first Compliant with all trivalent chromate finishes along with RoHS compliant electroless nickel finishing. Where the finish comes first since 1910. F.M. Callahan & Son, Inc. announces the introduction of RoHS compliant zinc yellow, clear and black chromates. In conjunction with this announcement we have a release of our RoHS compliant electroless nickel. F.M. Callahan &...

Read More »

Increase Workplace Safety, Manage Heavy Loads with Equipment from A-Plus Warehouse

A-Plus Warehouse carries a wide selection of commercial and industrial material handling equipment at affordable prices. Check out the video to learn more.

Read More »