Thermoplastic Elastomer meets Class VI standards.

Offered as extruded tubing or injection molded components, FlexiPrene(TM) pharmaceutical grade TPE (thermoplastic elastomer) may be heat sealed, welded, or sterilized by autoclave, gamma radiation, or EtO. Injection moldable material allows for leak-free connections and eliminates entrapment issues in manifolds and assemblies. Free of silicone oils and animal-derived ingredients, flexible tubing...

Read More »

Washers, Spacers, and Stampings come in superalloys.

Available in over 2,000 materials, including wrought cobalt, iron, and nickel-base superalloys, Washers, Spacers, and Stampings can be produced in short, medium, or large run orders. Combination of outside diameters from 0.080-5.140 in. with variety of inside diameters, thicknesses, and materials enables millions of possibilities. Full range of metric sizes and large diameter washers also...

Read More »

Black Oxide System finishes heat-treated fasteners.

TRU TEMPÃ-® produces non-dimensional black oxide finish, directly over light heat treat scale, on all types of fasteners and other bulk-handled parts. Since it operates at 200Ã-

Read More »

Self-Adhesive LIMS are used in silicone-to-plastic molding.

Shin-Etsu Selective Self-Adhesive Liquid Injection Molding Systems (LIMS) provide primerless adhesion to variety of thermoplastic resins. Series KE2090 and KE2095 facilitate production of multi-component products with silicone rubber bonded to plastic using insert overmolding or co-injection molding. Formulations adhere to thermoplastic substrate, but not to metal surfaces of mold, and exhibit...

Read More »

Choosing the Right Material for Your Project

When choosing an appropriate metal material, the range of options is so broad that selecting the correct material for your unique application can be challenging. Different metals have characteristics that can affect weldability, ductility, and formability. Our new eBook outlines the unique properties and applications of popular metals including: Stainless Steel Brass Aluminum Copper Titanium

Read More »Roll Bending Service is offered for multiple materials.

Angle roll bending services are provided for materials such as aluminum, steel, stainless steel, brass, and bronze. Tooling exists for bending shapes, including round pipe, round and square tube, angles, and channel up to 4.50 in. OD. Other services are provided via CNC measuring devices and pipe and tube cleaning, finishing, and forming machines.

Read More »PWB Base Material is flexible and halogen-free.

Supplied in thicknesses of less than 50 microns, Cute printed wiring board (PWB) base material is manufactured by applying epoxy-based, low-elastic modulus thermosetting resin to coat and impregnate 20 micron or thinner glass cloth and then overlaying it with copper foil. Heat-resistant, environmentally friendly material is suited for multi-layer PWBs in portable digital products such as digital...

Read More »Maching Service offers water jet cutting option.

Waterjet Cutting platform is available for wide variety of materials including steel, stainless steel, aluminum, brass, bronze, plastics, rubber and exotic metals. Clean, single cutting process often eliminates secondary operations. HammerHead WaterJet uses 60,000 psi stream of water and abrasive grit to cut, shape, drill and finish any 2D design in sheet material up to 4 in. thick.

Read More »

Molding Material is offered in halogen-free formulation.

ISODAMP C-8002 thermoplastic molding material dissipates energy internally, at molecular level, minimizing vibration amplification at resonance to restore equilibrium to sensitive, precision systems. Injection-moldable formulation is environmentally clean, wear-resistant, and adhesive-friendly. Flame-resistant to UL 94 V-0, soft and pliable product is available in custom-engineered configurations...

Read More »

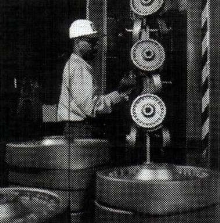

Shot Peening Service conforms to AMS-S-13165C specs.

Controlled Shot Peening process impinges surface of metal work-piece with spherical media at controlled flow rates and velocities, creating uniform layer of residual compressive stress at and below surface. Through wide inventory of SAE and AMS grade medias, company peens all types of components, ranging from aviation to automotive applications, and materials ranging from magnesium to steel.

Read More »EDM Machines/VMCs suit surface finishing applications.

Wire EDM Model FA10S features programmable flushing system, fine finish power supply, and non-isolated workpiece table. Sinker EDM Model EA12V includes multi-position work tank, which allows operator to set up while circulating dielectric fluid. ESPER II software offers multiple programs for measuring, power settings for burning, and orbital data for finishing. High-speed Model HC-658 VMC...

Read More »

Paratherm™ HR Heat Transfer Fluid: Higher Temperature Stability Leads to Longer Fluid Life

For the ultimate in heat transfer fluid performance, Paratherm offers HR Heat Transfer Fluid that is engineered specifically for closed loop liquid phase heating. When it comes to characteristics such as thermal stability and fluid degradation, Paratherm HR leads the industry in value and performance. See our video to learn how Paratherm is raising the bar for heat transfer fluids.

Read More »