Wisconsin Oven Ships One Electrically Heated Four Zone Conveyor Oven to Oil & Gas Industry

Wisconsin Oven Corporation announced the shipment of one (1) Electrically Heated Four Zone Conveyor Oven to a manufacturer in the oil and gas industry. The electrically heated conveyor oven has sufficient capability to heat 25 parts per hour with a heating time of 48 minutes and a cooling time of 12 minutes. Each chamber in this four-zone conveyor oven has a maximum temperature rating of...

Read More »

Sinto America Delivers a Y Track Spinner Hanger Blasting Machine

GRAND LEDGE, Mich., July 25, 2019 /PRNewswire/ -- Continuing their manufacturing excellence, Sinto America recently manufactured and shipped a KSB Y Track Spinner Hanger for NPK Construction Equipment. NPK is a leading manufacturer of hydraulic attachments, pedestal booms & more in construction & demolition industries. See Sinto's KSB Spinner...

Read More »

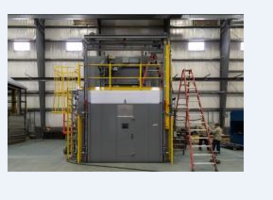

Wisconsin Oven Ships Gas Fired Batch Oven to the Aerospace Industry

Wisconsin Oven Corporation announced the shipment of one (1) Indirect Natural Gas Fired Batch Oven to a leading manufacturer in the aerospace industry. The batch oven will be used to cure composite materials. The batch oven has a maximum oven operating temperature of 500°F, work chamber dimensions of 10’ wide x 16’ long x 8’ high, and work zone dimensions of 8’ wide x 14’ long x...

Read More »

New-M30 and -L50 Geometries for Radius Inserts in Automotive and Aerospace Sectors

-M30 geometry optimizes groove milling of steel and cast iron automotive parts. Available for size 11 inserts with radius dimensions from 1.5 to 3.0 mm (0.059 to 0.118 in). -L50 geometry is offered for size 11 inserts with radius dimensions from 3.0 mm to 6.3 mm.

Read More »

Corrosive/Ultrapure Fluid Heat Exchanger Coils - Choosing the Right Strategy

Check out this white paper to learn which heat exchanger types are the best for high temperature performance in chemically aggressive applications.

Read More »

Thermal Product Solutions Ships Blue M Inert Gas Oven to Electronic Components Manufacturer

Thermal Product Solutions, a global manufacturer of thermal-processing equipment, announced the shipment of one (1) Blue M Inert Gas Batch Oven to a manufacturer of electronic components. This Blue M inert gas oven has a temperature range of 15°C above ambient to 593°C. The interior work chamber dimensions are 25” W x 20” D x 20” H. All seams and entrance ports in this batch oven were...

Read More »

Maguire Renames Its Unique Vacuum Resin Dryer âUltra-®â To Spotlight Drastically Lower Energy Consumption

Using Less Than a Tenth of the Energy Needed by a New Desiccant Dryer to Dry Resin, the ULTRA® Low Energy Dryer Saves Thousands of Dollars in Energy Costs per Year ASTON, PENNSYLVANIA, U.S.A., July 23, 2019: The world’s only vacuum resin dryer designed for plastics processors has a new brand name that reflects its proven capability to pay for itself through substantial savings in energy costs....

Read More »

Ultraflex Induction Brazing Steel Parts in Under 8 Seconds

[July 17th, 2019] UltraFlex Power Technologies - a leading manufacturer of digitally controlled induction heaters - recently shared the results from a customer-requested induction brazing scenario. The customer - a company operating in the sphere of Appliances and HVAC - was looking to replace the traditional torch heating-based brazing process for steel parts with induction brazing. The parts to...

Read More »

Bench Oven from Grieve Comes with 300 CFM, 1/3-HP Recirculating Blower

Equipped with eight (8) drawers with dimensions of 6” W x 13” D x 6” H with removable insert to close around cord. Features 2 in. insulated walls, Type 304, 2B finish stainless steel interior and exterior. Includes digital indicating temperature controller, manual reset excess temperature interlock and recirculating blower airflow safety switch.

Read More »

New QSW-308-1C and QSW-308S Features Three 10GbE SFP+ Ports

Swithces provide 10GbE solution to satisfy 10GbE/1GbE network infrastructures in homes and offices. Features plug-and-play for simple set-up and auto-negotiation for optimal speed. Equipped with eight Gigabit ports for users to optimize high-speed networking.

Read More »

New EchoTherm Model IC20XR Dry Bath Meets UL, CSA, and CE Standards

Comes with count-down timer in days, hours, minutes and seconds to 30 days; data logger; and RS232 I/O port. Measures 6.5 (165 mm) width, 8.75 (222 mm) depth and 3.5 (89 mm) height. Temperature ranges from -10°C to 110°C.

Read More »

TPA Motion Introduces Industry's First Compact Robotic Positioner for Medical Devices

TPA Motion's microplate handling robots are designed specifically for medical instruments and lab automation devices. Check out the video to learn more.

Read More »