Rapid Molding Process makes medical components.

Press Release Summary:

ZA-12 casting process uses permanent graphite molds to produce parts from ZA-12 zinc-aluminum alloy. Castings can include contours, surface elevations, holes, and other precise features. Process is suitable for making high-precision components for medical equipment and is economical in quantities of 300 to 20,000 parts per year. Company provides design, rapid prototyping, tooling and mold production, casting, and secondary machining.

ZA-12 casting process uses permanent graphite molds to produce parts from ZA-12 zinc-aluminum alloy. Castings can include contours, surface elevations, holes, and other precise features. Process is suitable for making high-precision components for medical equipment and is economical in quantities of 300 to 20,000 parts per year. Company provides design, rapid prototyping, tooling and mold production, casting, and secondary machining.Original Press Release:

Rapid Molding Process Is Ideal For Medical Components

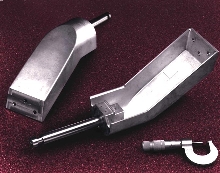

JAFFREY, NH- Graphicast's ZA-12 casting process is ideal for the manufacture of high-precision components for medical equipment. The Graphicast process, which uses permanent graphite molds to produce parts from ZA-12, a zinc-aluminum alloy, is an economical alternative to die casting, investment casting, sand casting with machining, and CNC machining of complete parts for production quantities from 300 to 20,000 parts per year. Graphicast's single-source production capabilities include in-house design, rapid prototyping, tooling and mold production, casting, and, if required, secondary machining. Typical turnaround time from finished CAD design to first article samples is 4-6 weeks.

The production of a swivel elbow for a medical equipment stand provides an example of Graphicast's comprehensive services. For this job, Graphicast not only produced the mold and cast the parts, but also provided custom steel shafts, assembled the shafts to the castings, and even designed reusable packaging to protect the finished parts in shipping and storage. Perpendicularity specifications were .002" to base and .008" to the opposite face.

ZA-12 zinc-aluminum alloy offers an excellent combination of physical properties, surface finish, and low cost. With approximately the same density as cast iron, ZA-12 alloy is harder, stronger, and better wearing than aluminum or bronze. It machines as easily as brass or bronze and more easily than cast iron or aluminum. Graphicast's exclusive LTA auto-pour technology produces castings with dimensional stability, low porosity, and exceptional consistency. No heat-treating is required. Typically, graphite mold castings can be produced in volume with critical dimension tolerances of ±.003" per inch for the first inch and ±.001" per inch for additional inches and surface finishes better than 125 microinches. Parts from the mold have a lustrous bright metal finish that in most cases requires no preparation or coating for corrosion protection. If desired, parts can be painted, powder coated, or finished with electro-coated acrylic or epoxy to simulate black anodized aluminum.

Castings can include contours, variation in surface elevations, holes, and other precise features. Graphicast offers comprehensive design assistance, and state-of-the-art software facilitates any modification to draft or radii required to accommodate the casting process. Parts are cast to near net shape and require no machining to meet tolerances. Secondary machining such as boring, drilling, and direct thread tapping are performed in house on precision CNC machining centers with rotary axes. Dedicated fixtures, custom designed by Graphicast engineers, maximize repeatability and minimize cost.

For more information, contact: Val Zanchuk, President; Graphicast, Inc.; P.O. Box 430; 36 Knight Street, Jaffrey, NH 03452; TEL: (603) 532-4481; FAX: (603) 532-4261; www.graphicast.com.