Bandsaw Blades cut wide array of materials.

Designed for general-purpose machine shops, Easy-Cut blades employ tooth design that permits blade to operate over large selection of materials. They are suited for use with non-ferrous materials from plastics, aluminum, and copper to AISI range stainless steel and tool steel. Prehoned 3868 TSS (Triple Set Stainless) blades, usable with AISI range stainless steel, eliminate need to run blade in...

Read More »

EDM Machines drill .014 in. diameter and larger holes.

Series FH Six-Axis Fast Hole EDM Machines separate tilting A axis from table-mounted B rotary axis, creating unobstructed work area. They include remote diagnostics, 3,000 rpm spindle, communications portal, 15 in. LCD screen, and remote pendant. All machines utilize Siemens 840 Di CNC controls as well as Siemens drives and motors, which feature absolute encoders to insure position is never lost.

Read More »

Vertical Machining Centers feature high stiffness.

Series XP3, Models 610, 760, 1000, and 1500 range in XYZ work envelope size from 24 x 20 x 24 in. to 60 x 26 x 24 in. They feature cast iron construction, dual-ball linear guides, and 45 mm ballscrews. SKF spindle offers radial stiffness of 60 lbf/0.00004 in. and axial stiffness of 70 lbf/0.00004 in. All models include chip conveyors, through-spindle coolant at 300 psi, and thermal compensation....

Read More »

CNC Vertical Machining Center has compact design.

With 73 x 81 in. footprint and X, Y, Z travel of 18 x 14 x 15, cast iron Interact 450 features customized Siemens 810D control and proprietary FastOp package with one-button macro operations. Machine provides 1,180 ipm rapid rates on all axes and 3 m/secÃ-² accel/decel rates. BT or CT 40 taper spindle with 13.4 hp motor provides speeds to 8,000 rpm. VMC also includes coolant system and...

Read More »

Direct Drive Linear Motors for Food/Beverage, Medical/Pharma & Packaging Applications

This eBook provides an overview of how direct drive linear motors can be an essential part of an efficient design ensuring the equipment operates and performs as intended.

Read More »

HMCs are suited for high-production environments.

Built on traveling column structure, HMC 700 line has 20 in. pallet size and 28 x 24 x 24 in. X, Y, Z work envelope. Heavily-ribbed cast iron throughout adds weight and mass for stiffness and overall rigidity, while guideways and oversized 45 mm ballscrews also contribute to stiffness and distribution of cutting forces. Line incorporates German-built, 40-taper SKF spindle; GE Fanuc control,...

Read More »

Vertical Machining Center offers 5-axis contouring.

Model 5AX 500 features 45 mm ballscrews, 30-tool ATC, and SKF 40-taper spindle with radial stiffness of 60 lbf/0.00004 in. and axial stiffness of 70 lbf/0.00004 in. Providing XYZ axes working envelope of 27.5 x 23.3 x 19 in., machine offers rapid traverse rates of 1,260 ipm and acceleration rates of 6 m/secÃ-². It includes 20 in. rotary/tilting trunnion table, through-spindle coolant, and...

Read More »

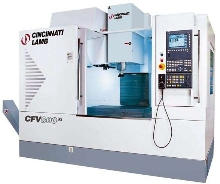

Vertical Machining Centers cut molds out of steel.

Available with CNC options from GE Fanuc and Siemens, CFV line of VMCs includes 4 models with X-axis travel up to 1,300 mm. Products have cast iron structure, provide 540 mm Y-axis travel, and accommodate 585 mm deep component. With 25 hp spindle as standard, users can select from 2 performance packages: Xi, with 12,500 rpm spindle and 30-tool toolchanger, or Si, with 20,000 rpm HSK-A63 spindle...

Read More »

Bar Machine suits high-volume applications.

Featuring hydraulic collet chuck and automatic parts unloading, CNC 30 G incorporates U-shaped cross slide gang tooling with T slots for tool-holder positioning. Machine has 94.5 x 86.6 in. footprint and includes interactive programming screens, 5,500 rpm spindle, 7.5 hp ac motor, and GE Fanuc 0i-Mate control. Max bar capacities are 1.625 in. round, 1.250 in. hex and 1.00 in. square, with max bar...

Read More »

Cobalt Steel End Mills suit aluminum applications.

Tri-Power Ski-Kut(TM) Series includes 3-flute, M42, 8% cobalt end mills suited for aluminum finishing operations. Flute form facilitates chip evacuation, while chip flow permits operator to maintain the same chip-load-per-flute as with 2-flute tool.

Read More »CNC Smart Spindle is suited for high-speed machining.

Closed loop, motorized SETCO(TM) 170 is equipped with ABEC Class 7 high nitrogen steel bearings, AirShield(TM) spindle seal system, and hybrid ceramic balls. Spindles up to 20,000 rpm are grease-lubricated, eliminating need for air-oil lubrication sub-systems. Liquid-cooled spindle operates from 0-18,000, 20,000, or 24,000 rpm. It delivers up to 40 hp at 12,000 rpm and 211 lb-in. torque under...

Read More »

General Pipe Cleaners Presents Lightweight, Powerful JM-1000 Mini-Jet

The lightweight, compact JM-1000 Mini-Jet clears grease, sand, and ice with a high pressure water jet.

Read More »