EXSYS Introduces Turning Machines and Innovative Gear Box Solutions at The Greenville Convention Center

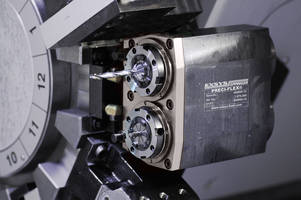

PRECI-FLEX modular tool holding system speeds turning center tooling changeovers and improves productivity with longer tool life. DECO-FLEX tooling interface adds flexible precision for small-part manufacturing and includes holders for Star CNC brand Swiss-style machines. EPPINGER BT and BM spiral bevel gearboxes provide minimized tooth clearance and optimal transmission properties.

Read More »

Face Grooving Tools operate as single or twin cutters.

Designed to fit large diameter Series 318 and Series 319 SW twin-cutter boring heads, Face Grooving Insert Holders can be used as single or twin cutter grooving tools for 2.087–118 in. diameters. Design allows for grooving depth up to .472 in., with minimum width of .079 in. and maximum of .375 in. Using boring tools as twin cutters, with simultaneous adjustment in radius and length, allows...

Read More »

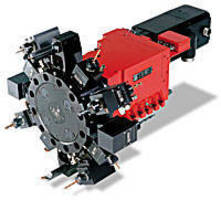

Disc-Type Tool Turrets mount in any position.

Designed for CNC lathes and turning centers, SAUTER Tool Exchanger Turrets are available in 6 frame sizes, each with non-lifting tool carrier having 8, 12, or 16 tool capacity. Bi-directional operating units are prepared for either axially mounted static tooling or combination of both static and live tooling. Featuring low kinetic design, turrets are extremely crash resistant. Optional central...

Read More »

Stick Electrode optimizes operator control and weld quality.

Available in 1/8 or 5/32 in. diameters, Hobart 610 features concentric design, ensuring even coating along entire length and consistent arc performance. Stick electrode exceeds AWS minimum specifications by offering tensile strength of 78,000 psi and yield strength of approximately 65,000 psi. To minimize cracking in low temperatures, product offers Charpy V-Notch impact values of 45 lb-ft at...

Read More »

What You Need to Know About Barrier Technology for Your Food Package

Learn about the Benefits of Barrier Technology

Read More »

Hydraulic Toolholder supports milling, drilling, and reaming.

Suited for high volume cutting, TENDO E compact can safely transfer torques up to 384 lb-ft at 20 mm clamping diameter. Universal toolholder provides vibration damping and precise run out accuracy of less than 0.0001 in. at 2.5 x D, protecting machine spindle and cutting tool from damage. Common spindle connections are available, including HSK-A63, SK40, BT40, CAT40, and CAT50 interfaces.

Read More »

Swiss Clamp System aids in ER collet clamping.

EZR Swiss clamp system is available with EZR Swiss clamp nuts, EZR wrench adaptor, EZR torque nut adaptor, and spanner wrench. System eliminates wrench slippage and losing clamping nuts in machine sump/chip bin. Standard box wrenches or 3/8 in. drive ratchet wrench with either EZR wrench adaptor or EZR torque adaptor help in tightening clamp nuts.

Read More »

REGO-FIX-® Highlighting Precision Toolholding Solutions at PMTS 2011

Indianapolis, Indiana - REGO-FIXÃ-® will be showcasing a variety of high precision toolholding products at PMTS 2011. The company will display products in booth #1025 at the show, which takes place on April 19 - 21 at the Greater Columbus Convention Center in Columbus, Ohio. REGO-FIX's swissQuick toolholding system provides a wide range of flexible models in various types (ER 8 - ER 25) and...

Read More »Visit CJWinter and Davenport Machine at PMTS 2011 in Booth #700

Rochester, NY - CJWinter Machine Technologies and Davenport Machine will be at PMTS (Precision Machining Technology Show) located at the Greater Columbus Convention Center on Tuesday, April 19th - Thursday, April 21st, 2011 in Columbus, Ohio in booth #700. The time to invest in new technology is now. Manufacturing continues to pick-up with many new business opportunities. If your application is...

Read More »

REGO-FIX-® Showcasing a Variety of Toolholding Solutions at AeroDef Manufacturing 2011

Indianapolis, Indiana - REGO-FIXÃ-® will be showcasing a variety of new toolholding products at AeroDef Manufacturing 2011, including multiple additions to its innovative powRgripÃ-® toolholding system. REGO-FIX will be displaying products in booth #1254 at the event, which will take place on April 5 - 7 at the Anaheim Convention Center in Anaheim, California. Through its unique approach...

Read More »Lyndex-Nikken Partners with Mimatic-® Tool Systems to Offer Leading European Live Tools for CNC Lathes, with an Initial Focus on Mazak Lathes

Mundelein, IL - Lyndex-Nikken continues to build upon its inventory of leading live tools with the addition of products from Mimatic Tool Systems' impressive line. Designed and manufactured to Mazak specifications in Germany, Mimatic live tools enhance the performance of CNC lathes. Mimatic live tool housings are machined from solid blocks of a special steel to achieve tight tolerances. Hardened...

Read More »

ISO-Certified Precision Machining and Contract Manufacturing Services from DFF

DFF is an industry leading contract manufacturer specializing in medium to high production precision machined components and electromechanical assemblies. Our 100 CNC machining centers and design-assist capabilities ensure our customers' needs are always met. Check out our video to learn more.

Read More »