Four-Axis Grinding Center offers automated loading capacity.

With 12-tray capacity, Dom Plus is suited for high-production grinding of indexable inserts on periphery with two K-Lands through integrated re-clamping. Machine's 180Ã-

Read More »

Radius Internal Cylindrical Grinders handle large workpieces.

WithÃ- workhead on simultaneously swiveling B-axis, STUDER S121, S131, and S141 offer thermal stability, mechanical rigidity, and interpolation from -60Ã-

Read More »

GMTA News of Note

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German metalworking machine builders, including Wera Profilator, K + G, Pittler, Praewema and WMZ, as well as Arnold lasers and Rosink parts washers.Ã- These machines are sold to the North American market exclusively by GMTA, primarily for gear and spline production, as well as other power...

Read More »

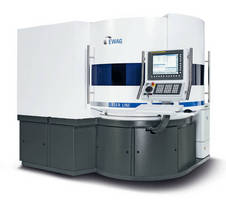

UNITED GRINDING's Vast, Advanced Technology to Stand Out at GrindTec 2014

Company to display several new innovations from WALTER, EWAG and STUDER in Hall 7-7050Ã- MIAMISBURG, Ohio – UNITED GRINDING, the largest single-source provider of complete and integrated grinding solutions, will showcase its latest grinding, eroding, laser and measuring innovations for general purpose and advanced tool and cutter production in Hall 7-7050 at GrindTec, taking place March 19...

Read More »

Peristaltic Pump Vs. i-FILL® Technology

Intellitech's advanced i-FILL® pumps are used by companies working in some of the world's most demanding sectors, delivering innovative, highly accurate and repeatable results, ensuring ultimate reliability and ease of use for all of our clients.

Read More »

Air-Powered Pencil Grinder features variable speed design.

Providing adjustable speed from 35,000–60,000 rpm, Variable Speed Pencil Grinder offers precision deburring, finishing, and engraving. Tool features non-slip ergonomic grip, one-touch pushbutton for on/off operation, and overhose assembly that helps direct air away from operator. Spindle Lock with through-hole enables quick accessory change with no need for 2 wrenches. Supplied with 1/8 in....

Read More »

Surface Grinder can be used in diverse range of applications.

Used for removing paint, thin set, adhesives, mastics, and other floor coatings, 55 lb SG7 features high-speed polisher and utilizes 7 in. dia diamond segment discs. Dual gas shocks dampen grinding forces and help produce level surfaces, while ergonomic frame lets operator work in fully upright position. Handle offers vertical height adjustment and allows use from either side of machine. When...

Read More »

UNITED GRINDING Schedules North American Tour for New STUDER S11

MIAMISBURG, Ohio – Beginning next month, UNITED GRINDING will make it possible for manufacturers to get in front of the latest precision cylindrical grinding technology without having to travel far. The company has plans to take its new compact, highly productive STUDER S11 for small workpiece production on a six-city tour across the United States as well as make the machine a focal point at...

Read More »Taking You Forward at IFFA 2013

DÃ-¼sseldorf - GEA Food Solutions presents developments in meat processing and packaging equipment at IFFA that help meat processors go forward to higher performance. Hygienic design and application specific solutions are recurring themes in a showing that features six product premieres and many enhancements on existing machines. GEA on two stands at IFFA There are many ways to add value,...

Read More »

Affordable Productivity from NCMT with Launch of Entry-Level Okuma Machines

New turning machine to make UK debut; machining centres also to be announced NCMT will launch at MACH 2012 a new range of early-entry machine tools from Okuma, a Japanese manufacturer better known for its high-end machining centres and lathes. Called GENOS, the programme comprises two machining centres and fourteen CNC turning centres, one of which, a twin-spindle model, will be under power at...

Read More »Concrete Surface Prep Kit combones power, ergonomics, airflow.

Suited for large area concrete surface grinding applications, 7 in. Angle Grinder Surface Prep Kit includes W24-230 large angle grinder as well as 7 in. dust control shroud and optional vacuum. Model W24-230, at 15 A, has rated speed of 6,600 rpm and loaded speed of 4,600 rpm and delivers 150 lb-in. of torque and 2,400 W of power. Made from virgin polyurethane, dust control shroud opens to let...

Read More »

Krueger Sentry Gauge Announces the Release of Two New Chemical Sight Gauge Models Designed for Aggressive Liquid Storage Monitoring

Krueger Sentry Gauge, a leader in chemical sight gauges, now offers the ultimate in aggressive liquid storage monitoring devices. From sulfuric and hydrochloric acid to bleach, and acetone, our products are designed with robust features that deliver a long and trouble-free service life. See our video to learn all about this new and innovative line of sight gauges.

Read More »