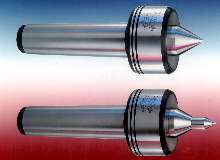

Live Centers suit manual and CNC turning applications.

Tough Little Centers (TLC) are offered in standard and extended-point models with shank sizes from 2MT-6MT. Short, thick point and oversized, double-row, angular-contact bearing provides rigidity. Needle roller bearing located within shank dampens vibration and reduces point deflection. Steel shield and neoprene seal protects bearing assembly from coolant and chips. Body and point are hardened...

Read More »

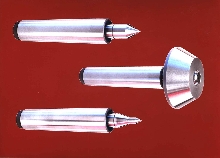

Live Center compensates for thermal expansion.

Spring-Type Live Center prevents damage to workpiece by sliding along z-axis. As heat from machining process causes workpiece to grow, rotating point is pushed back into body of center. Bearing, positioned between point and series of stacked disk springs, maintains thrust capacity. Low-profile body provides tool clearance and 0.0001 in. accuracy. Four point styles suit most applications.

Read More »

Increase Workplace Safety, Manage Heavy Loads with Equipment from A-Plus Warehouse

A-Plus Warehouse carries a wide selection of commercial and industrial material handling equipment at affordable prices. Check out the video to learn more.

Read More »