Power Lathe Chuck is sealed against chips and swarf.

Available in sizes from 165-500 mm, ROTA NCO offers clamping force from 95-330 kN with jaw strokes from 9-15 mm per jaw. Chuck is intended for vertical turning centers where contaminants are a hindrance. It offers options for automated part recognition in unmanned operations, as well as feed-through capabilities for coolant, air, or oil.

Read More »

Clamping Vise is resistant to contamination.

KONTEC KSL stationary clamping vise allows cubic workpieces to be clamped onto universal vertical machining centers or any 4th or 5th axes table. Available in 3 sizes with base jaw widths of 100, 125, or 160 mm, mounting holes located in jaw allow mounting of workpiece stops from both sides. Actuation is done from side of the fixed jaw via allen key equipped with ratchet, and vise securely clamps...

Read More »

Clamping System integrates into optical pre-setting device.

Combination of TRIBOS clamping system and Zoller optical tool pre-setting device allows user to pre-set tooling in holder, within microns. Tooling measuring up to 15Ã-¾ in. long, with dia up to 12Ã-½ in., and weighing up to 40 lbs. can be measured on unit. Pre-setter offers accuracy within 0.001 mm on display and within 0.002 mm on concentricity, with repeatability Ã-

Read More »

Tool Holder Extension has clamping dia. of 0.012 in.

TRIBOS Micro-Mini extension allows circuit board tools with straight shanks to be held directly in holder. Clamping process requires 30 sec by means of clamping device, either manual SVP-2 or automatic clamping SVP-3, together with corresponding reduction inserts. Run-out accuracy and repeatability of extensions is less than 3 microns. Due to rotational symmetric design, basic counter balance of...

Read More »

How EDM Controls Ensure Aerospace Validated Processes

Download this white paper to learn more about how wire EDM systems are used to validate aerospace manufacturing processes.

Read More »Horizontal Machining Center uses minimum quantity lubrication.

Near-dry Model RM80H features 80 mm diameter spindle capable of 8,000 rpm, and X, Y, Z axis travels of 20.8, 22.0, and 20.8 in., respectively. It provides deep hole drilling and rapid penetration up to 40 ipm, making it suited for forged steel and nodular iron crankshaft applications. System mixes air with fluid in spindle and applies droplets through tool to cutting surface. No more than 2 oz of...

Read More »

Hydraulic Toolholders offer radial length adjustment.

TENDO clamps different types of cutting tools with cylindrical shanks directly in toolholder without using intermediate sleeves. Clamping is done by steel sleeve surrounded by hydraulic fluid, and cutting tools with different shanks are held with concentricity of less than 0.002 mm. Hydraulic, completely closed system absorbs vibrations inherent in cutting or grinding processes, resulting in...

Read More »

Toolholding System provides alternative to collet style.

With run-out accuracy of 5 microns, SINO-T provides consistent support across entire clamping zone. Actuation is performed by using C-spanner wrench. Standard unit is fine balanced to G6.3 at 15,000 rpm. Available with CAT 40 and HSK-A 63 spindle interfaces, vibration-dampening system incorporates facility for Ã-

Read More »

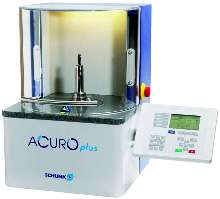

Balancing Machine is designed for toolholder systems.

Requiring 110 V power connection and 87 psi compressed air for operation, ACURO Plus can balance one complete system, consisting of toolholder and tool, within seconds in one or 2 planes. Adapter system with automatic clamping provides pulling forces equal to actual machine spindle. Balancing operations of toolholders with max weight to 33 lb and length to 13 -½ in. can be done at speeds of...

Read More »

Grinding Machines handle thin, pressure-sensitive parts.

Employing thin CBN or diamond abrasive wheel, Quickpoint Series 1000, 3000, and 5000 offer range of wheelhead configurations and varying numbers of flip over/tilting spindles. Tilting axis of wheel to horizontal workpiece axis creates relief angle that reduces contact line to point. Series can machine entire right and left shoulders, tapers, chamfers, radii, plunges, and relief grooves on both...

Read More »

Vertical Machining Center operates at 10,000 rpm.

Model VX650 offers X, Y, Z travels of 55, 26, and 25 in. with rapid traverses of 1,575, 1,575, and 1,181 ipm. Four-slideway structure in Y axis provides stability for heavy duty machining. Available with BT or CAT 40 tool shank, machine includes 20-tool ATC, centralized Fanuc 0IMB controller, and 63 x 25.6 in. table with load capacity of 2,866 lb.

Read More »

Does Your Parking Lot Make a Good First Impression?

To enhance its appearance by removing oil stains, Terminator-HSD uses micro bacteria to remove the stain without harsh chemicals, acids, or detergents. Check out the video to learn more.

Read More »