CNC Bore Grinder has 3-axis, vertical design.

Developed for high production bore grinding applications as well as small batch processing, GS:I-V has 48 x 72 in. footprint that simplifies manual or automatic loading. Machine features cast polymer base, balanced spindles from 30,000-90,000 rpm, and rotary diamond contour dresser. With max part diameter of 10 in. and length of 4 in., product utilizes Smart-Spindle(TM) acoustic touch dress...

Read More »

CNC Gear Hobbers feature GearSmart(TM) programming.

Able to handle workpiece diameters from 6-36 in., GS:H machines accept operator-entered workpiece and material parameters and GearSmart software calculates feeds and speeds. Products utilize Fanuc control, million-count encoders on all axes, servo-driven hob, and direct-drive linear axes. Pre-loaded ground ball screws provide consistent tooth spacing, and CNC provides data storage for hob life...

Read More »Vitrified CBN Grinding Wheel suits inconel grinding.

Suited for grinding hot section segments, AEROBOR(TM) removes bulk of material as well as tapers and radii and generates required finish quality. Wheel features 1.25 hr max machining time, minimal noise level, and reduced heat generation at cutting surface. With metal removal rates to 0.040 in./hr, it combines metal removal rates of CBN with dressability of vitrified wheel, leading to decreased...

Read More »

Gear Grinder rough and finish grinds gears in one setup.

Built on mineral-filled cast polymer base, 6-axis GS:G2 produces gears from 1-12 in. dia, employs near net-shaped or hobbed gears, and requires 15 min of setup. Machine requires users to install proper tooling and enter part form, dress, and grind parameters into control in order to start-up new jobs, while menu-driven screens and Gear Smart(TM) Programming facilitate operation. Product features...

Read More »

Direct Drive Linear Motors for Food/Beverage, Medical/Pharma & Packaging Applications

This eBook provides an overview of how direct drive linear motors can be an essential part of an efficient design ensuring the equipment operates and performs as intended.

Read More »

Right-Angle Sander/Grinder utilizes 1.2 hp motor.

Top CatÃ-® Series 4101 RA operates at 12,000-15,000 rpm with air consumption of 30 cfm. Longest tool in series is 10.5 in. with body diameter of 1.5 in. Available in steel version or with aluminum case material, unit is suited for OEM finishing and refinishing/revitalizing of turbine blades and other metal removal and cleaning applications. Exhaust configurations of front and side are...

Read More »Robotic System automatically compensates for tool wear.

Suited for single-pass bore finishing operations, robotic system automates bore finishing process and monitors all progressively sized diamond tools individually in order to make necessary size compensations due to tool wear. Machine incorporates central robotic arm to pick-up and move incoming parts from machine to machine. System also includes gauge unit, system controller, and unit designed...

Read More »

Solid Carbide Roughing End Mill suits die and mold steels.

In roughing and semi-finishing operations, HSC Feed operates with chip loads up to .031 in. per tooth and cutting speeds over 650 sfm. Product combines sub-micrograin substrate and proprietary AL2 plus PVD titanium aluminum nitride coating for wear-resistance and toughness. Run at table feeds exceeding 500 ipm, product performs high-feed milling of materials with hardness up to 60 Rc in addition...

Read More »

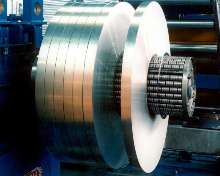

Core Slip Rewinding System provides constant coil tension.

Slip Tech system consists of core winding surface made entirely of bearings, which reduce friction between core surface and winding drum. This eliminates excess tension in individual rewound coils during build up, resulting in ability to maintain consistent coil tension because each strip is independently tensioned from core to finished coil OD. Product can also eliminate need for looping pits in...

Read More »

Press Brakes feature PC-based graphical controls.

Available in 14 sizes from 16-2,000 tons with standard bed lengths from 4-24 ft, PROFORM Press Brakes offer Ã-

Read More »

Power Chuck offers clamping forces from 26-500 kN.

Providing jaw strokes from 10-18 mm per jaw, 2-Jaw Rota 2B includes integrated feed-thru and mounting features for irregular workpieces. Seals and wipers placed in crucial areas help reduce contamination of chuck body and facilitate grease retention. Chuck is suited for both turning centers and stationary applications.

Read More »

TPA Motion Introduces New Curved Linear Rail Guides: the CR40 Series

For the ultimate in precision open and closed loop guided motion systems, TPA Motion is the leader in curved rail, liner guides. We specialize in engineering excellence, with products that exhibit an elevated level of precision, delivering robust performance, even under the most challenging conditions. See our video to learn more.

Read More »