Model 2175B Track Cutter is Made from High Carbon Steel with a Non-Glare Finish

Equipped with cushioned Xuro-Rubber™ hand grips and a Light Touch™ return spring. Features Micro-Shear® blade that bypass cutting action which leaves clean square cuts . Used in HO, N and Z (code 100) scale modeling applications.

Read More »

Caldwell Custom Lifting Device for Cryomodule Assembly

Rockford-based The Caldwell Group Inc. has manufactured a customized lifting device that is being used during assembly of cryomodules at the Fermi National Accelerator Laboratory (Fermilab) in Batavia, in its home state of Illinois, U.S. The project was awarded to Caldwell distributor John Sakash Company Inc., also of Illinois. The process requires precision assembly apparatus, as Fermilab builds...

Read More »

New 720-ton Injection Molding Machine Offers Fractional Range of 107 ounces

Provides clamping force of 46 to 720 tons. Offers production flexibility for large part injection molding with its higher tonnage capability. Improves capacities of 118 molding presses.

Read More »

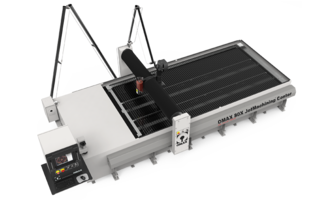

OMAX-® to Showcase Full Range of Waterjets at FABTECH 2019

KENT, Wash., July 24, 2019 – At FABTECH 2019, OMAX® Corporation will demonstrate the power of abrasive waterjets on four different machine models. Show attendees can explore each of the OMAX product lines to find out which waterjet is right for their particular applications. In booth A5731 at McCormick Place, Chicago, November 11-14, OMAX will showcase an OMAX 80X with a Tilt-A-Jet, a MAXIEM...

Read More »

Ergonomics Is Good Economics

While you don't need an MD to know that ergonomic designs are good for physical health, you probably didn't realize that these designs can actually be good for your economic health too.

Read More »

New S-EW3 Wire EDM Features Auto Wire Threading

Features 5-axis linear guide way, 5-axes AC servo motors, ball screws, high stability mechanical structure and a reliable AWT system. Includes keyboard, mouse stand, RS-232, USB disk, network and FTP. Programmable reduced power settings eliminate wire breaks on lead-in cutting.

Read More »

New-M30 and -L50 Geometries for Radius Inserts in Automotive and Aerospace Sectors

-M30 geometry optimizes groove milling of steel and cast iron automotive parts. Available for size 11 inserts with radius dimensions from 1.5 to 3.0 mm (0.059 to 0.118 in). -L50 geometry is offered for size 11 inserts with radius dimensions from 3.0 mm to 6.3 mm.

Read More »

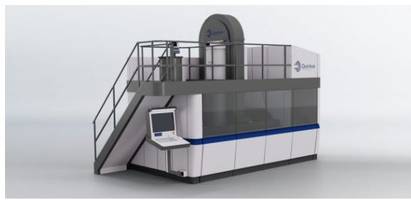

Quintus Technologies HIP Expands Accurate Brazingâ™s Thermal Processing Capabilities

Heat Treating Specialist Broadens Service Offering and Compresses Lead Times with New Hot Isostatic Press VÄSTERÅS, SWEDEN (PRWEB) JULY 23, 2019 Accurate Brazing, a full-service provider of specialized heat treating solutions, will add hot isostatic pressing to its thermal processing capabilities with the installation of a Hot Isostatic Press (HIP) from Quintus Technologies. The press, model...

Read More »

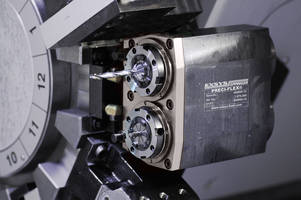

EXSYS Introduces Turning Machines and Innovative Gear Box Solutions at The Greenville Convention Center

PRECI-FLEX modular tool holding system speeds turning center tooling changeovers and improves productivity with longer tool life. DECO-FLEX tooling interface adds flexible precision for small-part manufacturing and includes holders for Star CNC brand Swiss-style machines. EPPINGER BT and BM spiral bevel gearboxes provide minimized tooth clearance and optimal transmission properties.

Read More »

SDP/SI Expands Timing Belt Inventory

Improving Service to Meet Customers’ Needs for Quick Turnaround June 27, 2019 – Hicksville, NY – Stock Drive Products/Sterling Instrument (SDP/SI), a leader in providing mechanical based design, engineering, and precision manufacturing services for critical motion control and small power transmission applications is proud to announce an expansion of their timing belt inventories resulting...

Read More »

New Hera 30 Features Siemens 828D Control

CNC gear hobbing machine includes streamlined dialog programming with visual examples to guide users and accelerate training. Accommodates parts up to 127 mm long with a maximum axial travel of 90 mm from 65 mm to 155 mm axial position. Provides 8 CNC axes, 1 module pitch rating, 40 mm maximum workpiece diameter and 10,000 rpm maximum hob speed.

Read More »

SpillVak Absorbs Up to 6X More Fluid Than Rock- and Clay-based Absorbents

Are you struggling to find an absorbent that doesn't result in at least some leaching? SpillVak outperforms all rock and clay-based materials. Check out our video to learn more.

Read More »