Machines process diamond/CBN wheels for grinding systems.

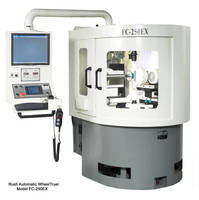

Designed for processing flats, angles, and radii on diamond/CBN single wheels and multiple wheel packs, Models FC-250EX and FC-700EX Automatic Diamond and CBN Wheel Truing and Dressing Machines feature PLC-controlled, automatic dressing cycles with servo-driven dressing wheel infeed, power swing, and oscillation. With wheel diameters up to 28 in., other features include ExVision, a...

Read More »Waterfeed Angle Grinder suits stone cutting.

Designed for use with diamond hole saws, 5 in. MP-1165W features spiral beveled gears and miniature brass ball valve with nylon seals to prevent leakage. Two-step safety lever prevents accidental start. Stainless steel spindle with wrench flats allows for removal of hole saw while dead handle offers stability and control when cutting. Grinder also features stainless steel feeder tube, 6 ft....

Read More »

Grinding Machine utilizes 20 hp spindle.

Utilizing 24 x 6.3 in. grinding wheels, Studer S36 HD wheel head version is suited for grinding precision automotive and hydraulic components. Flat and V guideways are coated with abrasion-proof Granitan S200 and provide vibration dampening. Digital direct-drive, 3-phase servomotors power X- and Z-axes. Cross slide X-axis travel is 10.5 in. at speeds up to 195 ipm. Fanuc 16i digital control...

Read More »

Tabletop Grinder-Polishers provide sample preparation.

Programmable PowerPro(TM) Series prepares specimens using Zaxis(TM) Macro Material Removal System, which enables operators to remove material from specimens by desired depth. Two horsepower base motor and 10 or 12 in. dia platen allows up to 10 specimens to be simultaneously prepared. Mineral cast base is corrosion proof, non-conductive, and chemically inert. Additional features include LCD...

Read More »

Seal Stuff In, Seal Stuff Out

One of the best ways to make sure that your machinery stays up and running in the face of adversity is to make sure that it's properly sealed. Of course, it's not always easy to determine whether the integrity of your seals are up to par. How can you tell when you have a problem?

Read More »

Grinder processes conductive metals.

Molecular Decomposition Process Grinder removes metal by decomposing it with electric current, electrolytes, and abrasives. PCL-based system uses fuzzy logic and neural network technology. Offering max grinding depth of 4 cu in./min, machine features 8 x 18 in. table, 590/118/118 ipm X/Y/Z rapids, 0.0002 in. positioning accuracy, and 5 hp spindle motor that peaks at 3,600 rpm. Resin-bonded wheels...

Read More »

Bench Grinder performs sanding and polishing tasks.

Model MLT3400 Belt and Disc Sanding Machine Tool roughens and fine finishes while sharpening and shaping various materials. Unit is equipped with belt that adjusts horizontally and vertically, allowing for finish into sharp corners. Adjustable, detachable miter table provides precise measurements. Sanding is accomplished through rubber contact wheel, free 100-grit belt, or free 80-grit disc....

Read More »

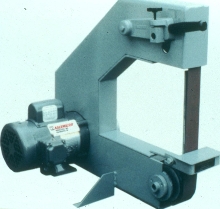

Belt Grinder has open area design for easy access.

Model BG272 benchtop belt grinder is equipped with 5 in. lower contact wheel, 1 HP TEFC direct drive motor, and 7200 rpm belt speed. Throat is 10 in. high x 13 in. deep. Unit measures 24 in. long x 12 in. wide x 24 in. high, and weighs just 80 lbs.

Read More »

Clear Clogged Drains Faster with General Pipe Cleaners' Kinetic Water Ram

The Kinetic Water Ram by General Pipe Cleaners clears out clogged pipes quickly using kinetic energy. The Ram is so simple to operate, anyone can use it. Check out the video to learn more.

Read More »