Balancing Machine is designed for toolholder systems.

Press Release Summary:

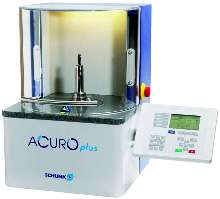

Requiring 110 V power connection and 87 psi compressed air for operation, ACURO Plus can balance one complete system, consisting of toolholder and tool, within seconds in one or 2 planes. Adapter system with automatic clamping provides pulling forces equal to actual machine spindle. Balancing operations of toolholders with max weight to 33 lb and length to 13 ½ in. can be done at speeds of 300-1.100 rpm. Dimensional balance accuracy is less than 1 g mm.

Original Press Release:

ACURO Plus - New Balancing Machine for Toolholders from SCHUNK

SCHUNK Inc. introduces a new balancing machine, ACURO Plus, which makes the balancing of toolholders much easier. This balancer has minimal requirements with regard to space and energy, while at the same time offering an attractive design. In order to operate the unit, an operator must have a conventional 110 V power connection and 87 psi compressed air. Within seconds, a complete system, consisting of a toolholder and a tool, can be balanced in one plane or, for particularly long systems, also in two planes. An adapter system with automatic clamping provides the same pulling forces as an actual machine spindle. Via a menu-driven system, the basic data input is done, e.g. desired balancing tolerances in balance quality (optionally G or Q) as well as the specific density of material. Balancing operations of toolholders with a maximum weight of up to 33 lbs and a maximum length up to 13 ½" mm can be done at a speed of 300 RPM up to 1.100 RPM. The dimensional balance accuracy is less than 1 gram millimeter. The tool data administration on the machine comprises up to 1.000 tools and tool parameters. Depending on the balancing process of the toolholders, the user can choose between the measuring methods index measuring or spindle compensation. At the end of a measuring operation, the actual position of the unbalance is shown on the operating screen. Furthermore, the unbalance can be shown directly on the tool by a red laser light. To compensate the determined unbalance, the operator has various options. He can remove the material by drilling or milling. For this option, the best position for material removal is calculated by a software algorithm calculating the position of the balancing bore (size of bore diameter and depth). The other option is that the imbalance compensation can be done using balance rings or balancing weights / screws. During this operation, the operator receives the exact positioning- or screw-in depths. ACURO plus is a cost-efficient balancing machine, that is quick and easy to handle, and stands out with precise measuring capabilities and repeatability. Even grinding wheels and other workpieces with a maximum diameter of 13" can be balanced with this machine. SCHUNK INC. 211 Kitty Hawk Drive Morrisville, North Carolina 27560 Phone: 919.572.2705 or 800.772.4865 Fax: 919.572.2818 www.schunk-usa.com info@schunk-usa.com