Cylindrical Vacuum Dryers suit chemical process industries.

Providing full vacuum and internal pressure operation, Cylindrical Vacuum Dryers range from 1 to over 500 cu-ft, and can be constructed from variety of materials such as hastelloy and stainless steel. Units feature dimpled and baffled jackets on trough sides and endplates rated to 200 psig. Internal agitation consists of paddle design, set at opposing angles, to insure material being dried is...

Read More »

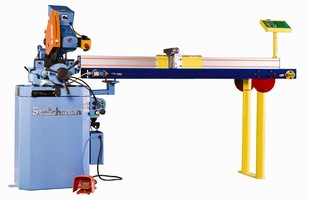

Measuring System mounts to metal or wood working machinery.

Enabling accurate setting of material length, CPO 350 ScotchmanÃ-® Advanced Measuring System allows feeding of material in 4-24 ft lengths from left to right or right to left. Loc Stop and Multi-Loc systems are manufactured using stainless steel investment casting, and do not slip.

Read More »

Universal to Present Leading-edge Placement Technology at Mexitronica 2006

Universal Instruments has announced plans to showcase the highly flexible AdVantis AX-72 and Quadris-S machine sets from booth #718 at this year's Mexitronica, being held over October 10th - 12th in Guadalajara, Mexico. An example of the AdVantis Platform's inherent flexibility, Universal's AdVantis AX-72 display will highlight one of the most adaptable models in the AdVantis collection. A...

Read More »

Advances in Honing Technology Help Small Engine Manufacturers Meet Emissions Standards

New honing technology from Sunnen Products Company can help small engine manufacturers meet or exceed today's strict emissions standards. The new technology can be found in a number of Sunnen honing machines including the new SV-1000 vertical honing system. The SV-1000 incorporates a WindowsÃ-® based CNC operating system to ensure the most precise bore geometry possible ...and tighter bore...

Read More »

Saving Energy with Efficient Belt Drives

By introducing energy efficient belts on electric motor drives, you can implement a simple, cost-effective solution to achieve energy savings in your facility.

Read More »

Toyoda's FH-S Series' High-Spindle Speeds Achieve 30 Percent Faster Cycle Times

Arlington Heights, IL - Toyoda Machinery's FH-S Series horizontal machining center increases throughput by pairing high spindle speeds with faster non-cutting operations, resulting in 30 percent faster cycle times. The FH450-S is a fast and powerful 40-taper HMC, and has been designed for quick acceleration and deceleration. It has a significantly larger work envelope than comparable machines,...

Read More »New at IMTS this year from Allied Machine & Engineering Corp.

Allied Machine & Engineering Corp. (AMEC), the leading manufacturer of replaceable tip drilling systems, is pleased to announce the next level of hole making technology for the metal cutting industry. GEN3SYS(TM), AMEC's newest, and most advanced drilling system, will be showcased and demonstrated at IMTS, September 6-13, 2006. Among the various upgrades, GEN3SYS(TM) offers a patent pending...

Read More »Sharp CNC Displays the Remarkable ST-20 CNC Lathe at IMTS 2006

Torrance, CA - Sharp CNC will display their amazing CNC Turning Center ST-20 at the IMTS show in Booth A-8474. Sharp CNC ST-20 has a swing capacity of 22.8 and maximum turning length of 18.1 . The reliable Fanuc control makes the ST-20 easy to operate. With special Sharp CNC features like word-processor editing, one-button features, multi-function jog handle, and Manual Guide Programming, you'll...

Read More »

Sunnen Honing Systems Improve Reliability of Hydraulic Components

Sunnen Products Company has introduced new technology to help hydraulic component manufacturers conform to zero-leak standards and greatly reduce warranty issues due to component leakage. The advanced technology is incorporated into a number of Sunnen honing systems, including the VSS(TM) Vertical Single Stroke HoningÃ-® System-- a multi-spindle, workhorse that meets the demand for critical...

Read More »

New Norton BRGg Gear Grinding Wheels Generate up to Five Times Longer Life on Parallel Axis Spur and Helical Gears

--High Performance BRGg Wheels for Gear Applications Can Be Used at Greater In-Feed Rates to Reduce Cycle Time-- WORCESTER, Mass., May 17, 2006 -- BRGg-VPHS high-speed wheels are the latest addition to the complete line of grinding wheels engineered for superior worm and angle gear grinding. Norton BRGg wheels are designed to reduce grind cycle times by increasing metal removal rates. The...

Read More »

CNC Tool & Production Grinder. Grinders of the Future, Here Today from Schütte

For the grinding of Medical Rasps, SchÃ-¼tte will introduce the first PC based program for these complex tools. Previously requiring working knowledge of programming utilizing a CAD-CAM system, the SIGS based program for RASPS is now available in a menu driven format. Combined with the SchÃ-¼tte linear technology for axis movement and Automatic Wheel Changing, the WU305 Linear continues...

Read More »

5 and 13 Micron Resolve Columns with Greater Bed Stability

Jordi Labs provides materials solutions that set the standard for innovation and quality. Our line of GPC and GFC columns are on the cutting edge of precision manufacturing and a result of our uncompromising commitment to quality and customer service. See our video to learn more.

Read More »