Customizable Spindles reach speeds of 2,000,000 DmN.

ProMetrix(TM) belt-driven spindles are capable of 12,000, 15,000, 18,000, and 20,000 rpm. Available in block, cluster, and cartridge designs, they offer variety of bearing configurations, hybrid gear types, lubrication methods, spindle noses, belt drive packages, and drawbars. Units feature permanent grease-packed or air-oil lubrication, and can be horizontal, vertical, angular, ceiling, and...

Read More »

Repair System fixes cracked bolt hole threads.

Based on Spiralhook(TM) thread geometry, Full-Torque(TM) thread repair system restores strength and new threads simultaneously. Available in most inch and metric sizes, system increases strength of casting when bolt or stud is torqued into insert. It pulls up on insert, increasing load on Spiralhook threads and radial drawing force of threads. System contains crack and prevents future damage...

Read More »

Machining Centers feature traveling column design.

Providing surface finishing and roughing operations, Model VTXV features stationary table capable of holding parts over 4,400 lb, and offers X, Y, Z travels of 31.5 x 27.5 x 20 in. Model VTXU, suited for machining multi-sided parts, allows 2-axis motion of trunion table to be separated from 3-axis motion in traveling column. For small batch processing, horizontal Model HTX500 features 500 mm...

Read More »

CNC Grinder provides creepfeed and flat surface grinding.

Suited for single-piece and batch production, Precimat 306 CNC features 300 x 50 x 76.2 mm grinding wheel, grinding range of 600 x 300 mm, and 5.9 kW variable-speed main spindle that achieves speeds from 5,100 rpm. Linear guideways in all axes consist of 6-row ball bearing systems. Work area is entirely enclosed to contain high-pressure coolant. Siemens 840 D CNC control provides 26.4 cm color...

Read More »

A Guide to Quality Control of the SMT Process

The printed circuit board (PCB) manufacturing process begins with cutting-edge equipment capable of accurately picking and placing up to 40,000 components per hour. This innovative equipment keeps error rates extremely low, and those defects that do occur are quickly caught by sensitive laser and optical inspection equipment.

Read More »

CNC Grinding Machine masters PCD/PCBN applications.

To grind PCD and PCBN tools and inserts, 4-axis CNC Easygrind automatically regenerates grinding wheel. Swiveling 3D measuring probe inspects cutting edge of tool to be ground and automatically transmits compensation data relative to infeed rate. GE Fanuc CNC control uses Windows-based software, permitting conversational or real-time programming of tools. Simulation program displays grinding...

Read More »

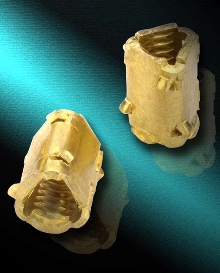

Threaded Inserts suit high-volume fastening applications.

Triangular-shaped, brass DeltaForm(TM) Inserts for plastics offer alternative to traditional inserts or thread-forming screws. Retention barbs facilitate insertion in round holes and prevent spin upon installation. Flange tabs on either end orient insert in hole before installation and form flush surface with plastic component when installation is complete. With thread size of #6-32, inserts are...

Read More »

Air Plasma Cutting System is suited for metal fabricators.

Equipped with 1Torch(TM) plasma torch and ATC(TM) (Advanced Torch Connector) quick disconnect, CUTMASTER(TM) 81 lets operator switch torches between hand and machine torch applications, replace damaged equipment, and add or remove lead extensions to match job requirements. It features 60 A cutting power and 1Series start technology. Rated for 1 in. max cut capacity, system is suitable for cutting...

Read More »

Circular Saws feature 15 A motor.

Series CS10 and CS20 Circular Saws with composite footplate resist bending under pressure and glide easily across all surfaces, including wet wood. Integrated blower removes dust and ensures clear line of sight. Depth detent system improves accuracy of cut. Bevel scale and positive detent systems allow users to find detents at 22.5Ã-

Read More »

Milling Spindle works with 5-axis machining centers.

Water-cooled MFW-2310/24 has 230 mm dia and uses hybrid (steel races with ceramic CERBECÃ-® balls) angular contact bearings. Rated for constant torque of 62 Nm up to 10,800 min-1, it features HSK-A63 tool clamping system with rotary union that allows cooling through tool. Tools with diameters from 20-50 mm and cutting speeds to 4,000 m/min can be used. Spindle is designed for machining...

Read More »

Winding System winds ferrous and non-ferrous metal strip.

Model 620 features oscillating spindle that allows material to remain in fixed position while spool moves back and forth. Accurate traverse and pitch control from 1/8 to 1Ã-½ in. minimizes camber and results in solid, damage-free wind build. System is suited for secondary operations such as single strand rewind lines or converting pancake coils into traverse wound stock, as well as level...

Read More »

Acoustic and Thermal Solutions for Original Equipment Manufacturers

Technicon's products solve the most complex noise pollution and thermal problems and improve product marketability. Check out the video to learn more.

Read More »