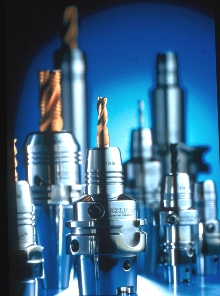

Toolholders use concentricity to hold tools.

SK, BT, and HSK toolholders are manufactured with hydraulic chucks in extended, and slim extended lengths from 63.5 to 200 mm. Guaranteed run-out of 0.0012 in. is maintained, and clamping forces are rated to 23,000 lbs. Shank-holding system with internal piston forces sleeve around cutting tool shank. Clamping area remains almost dry and high torque transmission is accomplished via metal to metal...

Read More »

Air Powered Saw cuts round pipe square.

APS-438 3 hp saw and WrapTrack clamps around circumference to cut pipe from 6 to 60 in. dia with Ã-

Read More »

Die Grinder operates at variable speeds.

Rated at 7.5 A and 900 W, GE900 Plus has 27 lb-in. of torque, making it suitable for grinding internal surfaces in polishing and finishing applications. It is geared to run at lower rpm, increasing number and type of usable accessories for sanding, polishing or buffing, such as flap wheels and non-woven abrasive finishing wheels. Variable speeds from 2,500 to 6,000 rpm allow it to grind and cut...

Read More »

Rotary Draw Benders handle difficult geometries.

Patriot(TM) is available in 17 models for bending tubes in HVAC, automotive, and appliance industries. Models range from 3/8 to 1 in., and can handle geometries up to 4 radii with no tool change. Features Windows-based PC and software with programmable feed for any bend and automatic crash prevention. Options include automatic load and unload system, wiper die, powered follower, 5/16C collet...

Read More »

A Guide to Quality Control of the SMT Process

The printed circuit board (PCB) manufacturing process begins with cutting-edge equipment capable of accurately picking and placing up to 40,000 components per hour. This innovative equipment keeps error rates extremely low, and those defects that do occur are quickly caught by sensitive laser and optical inspection equipment.

Read More »

Vertical Machining Center has 0.9 second tool change time.

Variaxis 630 offers rotary table with tilting angle of 150Ã-

Read More »

Machining Center integrates multiple processes in one setup.

Variaxis 500 offers rotary table with A-axis tilting angle from -120Ã-

Read More »

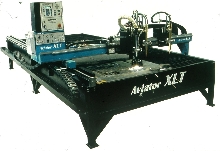

Plasma Cutting System makes shapes from sheet metal.

Aviator(TM) XLT has Burny(TM) 1250 Plus microprocessor CNC control for precision motion control of high-speed plasma and oxy-fuel cutting. It can cut 12 ga steel at 250 ipm or 1/4 in. stainless at 100 ipm. FastCAMÃ-® CAD/CAM automatic nesting software is included to process CNC files. Various models cut everything from thin gage sheet metal to 3/4 in. plate. Pak Master 150XL(TM) is for...

Read More »

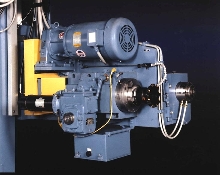

Drilling System is equipped with OTT hydraulic drawbar.

Mold block deep hole drilling system offers optional secondary operations head (EZ-HEAD) for milling up to 5 in. dia, tapping from 1.5 to 11.5 NPT (max), and counter-boring to 3 in. dia. Combination gun drill/BTA machine has 2 in. dia drilling capacity and 84 in. drilling depth (stroke). Four-axis machine features 84 x 84 in. work table with load capacity to 100,000 lbs. Its column provides 84,...

Read More »

Lathe Tool Setting Arms have DIN rail mounted interface.

Model HPPA manual push-down/pull-up tool setting arm resides permanently in machine's working envelope. When not in use, arm is locked securely away from workpiece. Model HPMA motorized tool setting arm provides automated tool setting and in-cycle broken tool detection. Model HPRA removable tool setting arm is manually inserted and removed. Arms fit chuck sizes from 6 to 24 in. and block tooling...

Read More »Post Processor generates NC code.

VEGAPost 3/5 axes NC Post Processor allows for multiple files to be selected for posting, displays which files are done, and flags data errors. It includes feedrate, rapid command, and spindle speed override; axis sweeping, mirroring, and scaling; reverse data; and insertion of cycle commands. Five Axes features include head unwinding/rewind, tool length compensation, prompting for tool...

Read More »

General Pipe Cleaners Presents Lightweight, Powerful JM-1000 Mini-Jet

The lightweight, compact JM-1000 Mini-Jet clears grease, sand, and ice with a high pressure water jet.

Read More »