Toolholders use concentricity to hold tools.

Press Release Summary:

SK, BT, and HSK toolholders are manufactured with hydraulic chucks in extended, and slim extended lengths from 63.5 to 200 mm. Guaranteed run-out of 0.0012 in. is maintained, and clamping forces are rated to 23,000 lbs. Shank-holding system with internal piston forces sleeve around cutting tool shank. Clamping area remains almost dry and high torque transmission is accomplished via metal to metal contact at all spindle speeds.

SK, BT, and HSK toolholders are manufactured with hydraulic chucks in extended, and slim extended lengths from 63.5 to 200 mm. Guaranteed run-out of 0.0012 in. is maintained, and clamping forces are rated to 23,000 lbs. Shank-holding system with internal piston forces sleeve around cutting tool shank. Clamping area remains almost dry and high torque transmission is accomplished via metal to metal contact at all spindle speeds.Original Press Release:

Complete Line Of Toolholders Now Manufactured Due To Plant Expansion

MORRISVILLE, NC. . .SCHUNK, INC. is currently under an expansion of their North American manufacturing facility. The manufacturing facility will be tripling the size and capacity. SCHUNK, INC. will now be manufacturing all of their standard TENDO hydraulic products for North America in North Carolina.

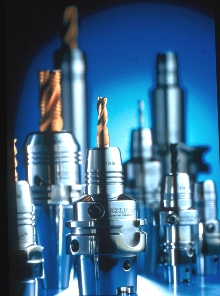

In addition to the standard CAT taper chucks, available in CAT 30, 40 & 50, SCHUNK will be manufacturing all SK, BT, & HSK toolholders. Along with the different tapers, SCHUNK offers the standard hydraulic chucks in extended, and slim extended lengths. Gage lengths are from 63.5 mm to 200 mm.

Even with the extra length chucks, the highest quality of guaranteed run-out of 0.003 mm (0.0012"), is still maintained. Add this to clamping forces up to 23,000 lbs. Or more will assure safety along with the accuracy at all spindle speeds over 15,000, balanced.

TENDO Hydraulic Chucks employ a unique and powerful shank-holding system. An internal piston pressurizes hydraulic fluid into a cavity surrounding a steel expansion sleeve. The high pressure uniformly forces the sleeve around the cutting tool shank.

Cutting tools are held with great concentricity. The enormous clamping pressure displaces oil or grease that may be on the tool shank, into the TENDO grooves in the expansion sleeve. As a result, the clamping area remains almost dry and high torque transmission is guaranteed with "metal to metal" contact at all spindle speeds. The hydraulic system also absorbs vibrations inherent in the cutting or grinding process. The results are very high T.I.R. accuracy and repeatability with in .003 mm (0.00012"); tool life can be extended up to four times; greatly improve surface quality of machining parts.

TENDO hydraulic chucks offer precise toolholding solutions for almost every manufacturing process. Chucks are available for high-speed & fine milling; heavy-duty milling in non-ferrous materials; machining in wood; HSC-Parallel-stroke milling; internal grinding; boring and chamfering; precision reaming; precision tool grinding, and some Workholding applications. With TENDO slotted, coolant-proof intermediate sleeves, different shank diameters can be handled with the same chuck for additional application versatility and tooling cost savings. And all TENDO hydraulic chucks are completely a closed system that operate free of dirt, coolants, lubricants, and chips to assure low maintenance and high operating lifetime.

For more information about the complete TENDO line of hydraulic chucks, special and standard products, and accessories contact SCHUNK, INC.; 211 Kitty Hawk Drive, Morrisville, North Carolina 27560; Phone 919.572.2705; 800.7SCHUNK; Fax 919.572.2818; or at www.schunk-usa.com.