Flange Spreader creates 3 in. gap in single pass.

AUTO-SPREADER(TM) flange spreader fits all sizes and classes of flanges and is available in both hydraulic and manual versions. Parallel serrated jaw design eliminates drift and slippage without use of wedges. Integral jaws open simultaneously allowing easy flange gasket replacement. Applications include turning blinds, impeller removal, bearing removal, opening vessels, gasket maintenance, and...

Read More »

Die-Cutting System processes magnetic material.

Sheet- or roll-fed die-cutting system is suitable for sheet or web production. Printed paper goes through heated over-laminate unit, then receives under-laminate of magnetic material. Optically registered die-cutter cuts out product. Finished product is knocked out of web at knock-out station, conveyed to operator, and remaining matrix is scrap cut. Product can also be left in web, sheeted into...

Read More »Correct-A-Chip Adapter operates up to 210-

Series 350000-HT lead-free Correct-A-Chip adapter enables users to upgrade from DIP devices to SOJ or SOIC devices with no PCB rework or redesign. It is offered on .300, .400, and .600 in. centers with 14, 16, 18, 20, or 24 pins. PCB is .062 in. Polyimid, rated at 260Ã-

Read More »

Spade Drilling System optimizes holder and insert performance.

Tru-Lok spade drilling system is offered in variety of straight shank, flange-type, and Morse-Taper shanks. Holders include quick change, back piloted, and combination drilling/secondary operation bars. Inserts ranging from 1/2 to 1 3/8 in. diameter are available in several grades of carbide and CPM high-speed steel, and in most common coatings.

Read More »Expanding Access: How to Get At-Home Medical Tests to Market and Patients

This e-book discusses how to get at-home medical tests to market and patients.

Read More »

Metal-Removal System suits gouging applications.

ARCAIR-MATICÃ-® N6000 provides control, uniformity, and productivity in automated air carbon-arc process gouging. Automatic Controller measures variations in arc voltage or amperage, compares them with pre-set standards, and takes action through feedback control. Its 1600 A Contractor supplies current to electrode contact shoe assembly in torch head. Torch head accepts gouging electrodes from...

Read More »Screwdriver features fatigue-reducing rubber grip.

Ergo Micro Torque (EMT) screwdriver has micro-adjustable external adjustment ring and positive locking system for quick completion of individual torque operations while preventing incidental torque adjustments. Bi-directional cam design slips free when specified torque setting is reached, eliminating risk of over-tightening fasteners. Color coded rings allow for differentiation between 23 EMT...

Read More »

Cyber Manufacturing System can sort and stack finished parts.

Laser CMS (Cyber Manufacturing System) combines efficiency of automated material retrieval, loading, cutting, and unloading with networked communication to downstream operations and other departments. CMS is able to schedule consistent production of up to 4 lasers. CAD/CAM system separates design into components, figures bend allowances, and issues dimensioned manufacturing drawings for cutting,...

Read More »Hammers are offered in combination and demolition models.

Models 11241EVS SDS-max and 11248EVS Spline are 1 9/16 in. units powered by 11 A motors. They provide 1,700 to 3,300 bpm operating at 0-170 to 340 rpm. Models 11240 SDS-max and 11247 Spline are 1 9/16 in. units powered by 10 A motors that provide 5.2 ft-lbs of impact energy, 400 rpm, and 3000 bpm. Combination Dual Mode Selector converts each unit from rotary hammer to hammer only. Models 11388...

Read More »

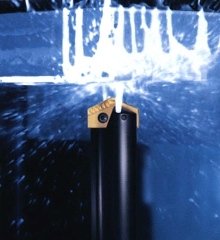

Drill provides chip control.

UnidrillÃ-® features UC-CCR chipbreaking geometry, which is suitable for drilling steels and stainless steels in diameters from 0.531 to 1.000 in. Corner radii reduce thermal stress, minimize break-out at back of hole, and improve surface finish. Clamping system assures precise insert location, and CVD coating (SC7052) allows high feed rates at low speeds.

Read More »

Cutters and Inserts handle heat resistant alloys.

Made with ceramic grade Kyon 2100, cutters work at speeds of 3000 sfm to rough mill nickel, cobalt, and iron based heat resistant alloys. Cutters and inserts also machine Waspalloy, Haynes 25, Inconel 718, Stellite and similar materials at cutting speeds of 2000 to 4500 sfm and feed rates of 0.002 to 0.005 ipt. Also available are KC9110 and KC9125 inserts, both with 3 coating layers: TiCN,...

Read More »

TPA Motion Introduces New Curved Linear Rail Guides: the CR40 Series

For the ultimate in precision open and closed loop guided motion systems, TPA Motion is the leader in curved rail, liner guides. We specialize in engineering excellence, with products that exhibit an elevated level of precision, delivering robust performance, even under the most challenging conditions. See our video to learn more.

Read More »