Drill provides chip control.

Share:

Press Release Summary:

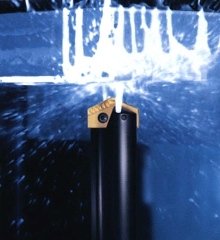

Unidrill® features UC-CCR chipbreaking geometry, which is suitable for drilling steels and stainless steels in diameters from 0.531 to 1.000 in. Corner radii reduce thermal stress, minimize break-out at back of hole, and improve surface finish. Clamping system assures precise insert location, and CVD coating (SC7052) allows high feed rates at low speeds.

Original Press Release:

Stellram's Patented Uc-Ccr Geometry Provides Optimum Chip Control For Drilling Applications.

La Vergne, TN--Stellram's UC-CCR geometry for Unidrill® features a patented chipbreaking geometry which is ideal for drilling steels and stainless steels where chipbreaking is a problem in a diameter range from 0.531" to 1.000".

The corner radii reduce thermal stress, improve tool life, minimize break-out at the back of the hole and improve surface finish. The patented clamping system assures precise insert location.

A new CVD coating (SC7052) allows high feed rates at low speeds for less rigid applications and deeper holes.

Stellram is a globally integrated technological leader in the development of metalcutting answers for turning, milling, threading, drilling and grooving applications.

Worldwide resources in materials, research, engineering and application expertise enable the company to be a single-source provider for all metalcutting needs.