Metal-Removal System suits gouging applications.

Share:

Press Release Summary:

ARCAIR-MATIC® N6000 provides control, uniformity, and productivity in automated air carbon-arc process gouging. Automatic Controller measures variations in arc voltage or amperage, compares them with pre-set standards, and takes action through feedback control. Its 1600 A Contractor supplies current to electrode contact shoe assembly in torch head. Torch head accepts gouging electrodes from 5/16 to 3/4 in. System prepares U and J grooves for welding, with ±0.025 in. depth tolerance.

Original Press Release:

ARCAIR-MATIC(R) N6000 System Takes Gouging to New Levels of Control, Uniformity & Productivity

St. Louis - July 1, 2002 - The ARCAIR-MATIC® N6000 Metal-Removal System provides a versatile combination of control, uniformity and productivity in automated air carbon-arc process gouging.

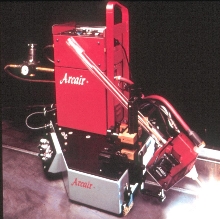

The N6000 system incorporates an advanced Automatic Controller (120VAC 60Hz or 220VAC 50Hz), 1600-amp Contactor and the latest Arcair Torch Head, with a nozzle assembly designed to reduce air turbulence and improve airflow for greater metal removal efficiency.

Versatile N6000 components make the system fit a growing list of old and new precise gouging applications. At the heart of the system's versatility is the Automatic Controller, which measures minute variations in arc voltage or amperage, compares them with pre-set standards and takes immediate action through its feedback control maintaining the precise arc gap for optimum gouging. The 1600-amp Contractor adds further to the system's versatility. It supplies proper current to a unique electrode contact shoe assembly in the N6000 Torch Head - a torch head that accepts the entire range of gouging electrodes from 5/16" (7.94mm) to 3/4" (19.05mm) with a simple adjustment.

The N6000 is ideally suited for metal fabrication, particularly in weld joint preparation where it is used to prepare uniform "U" and "J" grooves, maintaining groove depth within ±0.025" (0.635mm) tolerance. The system is also used extensively for seam backgouging and for removing defective weld and cracks. It can "Arc machine" large diameter kiln rolls and steel mill rolls where the removal of hard surface material is extremely difficult to accomplish with conventional means.

The N6000 is five times faster and requires 10 times less clean-up than an operator with a handheld torch.

Tweco Products is a division of Thermadyne Holdings, a global welding and cutting products company, with headquarters in St. Louis, Mo. The company is comprised of long-standing market leading companies representing many of the most respected brand names in the welding and metal fabricating industry. For more information, visit the Tweco web site at www.tweco.com, or phone 1-800-231-9353.