Mix Heads offer integrated shot counter.

Suited for polyurethane processing, mix heads include counter to help identify at what point (number of shots) mix-head performance is impaired by abrasion. Counter displays exact number of times the mix head cycles to allow users to map out trends and historical data, aiding in gauging preventive maintenance.

Read More »

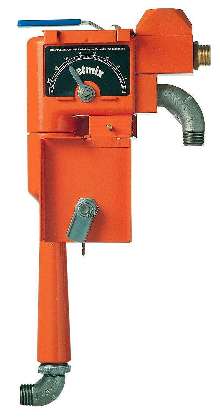

Coolant Mixer delivers accurate concentration of oil droplets.

Jetmix-® utilizes mixing-zone design, which creates strong shock waves of water vapor to break down coolant concentrate into highly homogenous emulsion of submicron size oil droplets. Resulting machining fluid provides stability, tramp oil rejection, and cutting-zone lubricity. Mixer is drum or wall mounted and connects to any tap water outlet providing 20-90 psi.

Read More »

Grinding Mill suits laboratories and pilot plants.

NETZSCH LabstarÃ-® incorporates interchangeable agitator systems, which allow it to grind various materials. Mill is convertible between TriNex(TM) and ZETA(TM) agitator systems. TriNex disks allow discrete pass milling, while ZETA system converts Labstar into peg agitation system for circulation milling. Unit processes batch sizes from 1 liter to 1 gal and operates in horizontal and vertical...

Read More »

Safety Mat reduces leg, neck, and back pain.

Ergonomic presence-sensing Comfort Step mat reduces worker fatigue while guarding personnel against injury from hazardous machinery. Switch on mat acts as safeguarding device, stopping dangerous machinery to load or unload stations, and change tools. Applications include places where liquids and fluids may be present, plastic blow-molding machines, assembly machinery, water-jet machines,...

Read More »

Site Amenities & Furnishings: Key Considerations When Sourcing A High-Volume Manufacturer

This white paper looks at the six key considerations when sourcing a high-volume manufacturer of site amenities and furnishings. Download now to find out more.

Read More »In-Line Sifters achieve capacities up to 1,000 lb/min.

Tru-Balance Sifters are inserted into vacuum or pressure pneumatic conveying lines as quality assurance tools for removing small amount of oversized impurities from product. They utilize pneumatic sieve compression system to elevate and lower upper dome assembly. Systems offer rapid access for sifter inspection, have no heavy domes to lift or hoist, and provide accelerated sifter closing. All...

Read More »

Paddle Mixer mixes and hydrates sticky materials.

Twin Rotor Hydramix operates in continuous flow without clogging. Self-cleaning design features close tolerances between rotor paddles and container walls to reduce material buildup. Unit has adjustable mixing speed and provides production rates up to 10 tons/hr. Rotors operate at 10 rpm, preventing particle damage during residence times of 20-30 min. Applications include hydration of phosphates...

Read More »Silt Density Index predicts membrane-fouling potential.

AutoSDI (Automated Silt Density Index) predicts membrane-fouling potential for reverse osmosis (RO) installations. Test Unit eliminates need for stopwatches, graduated cylinders, wet notes, calculators, and labor. Within 15 minutes after pushing single button, product gives users relative value for amount of suspended matter in feedwater streams. Field-calibrated unit runs continuously and...

Read More »

Variable Speed Mixer handles high viscosity materials.

Hand-held Model EHR23/1.2R is equipped with galvanized paddle that can mix concrete, mortar, and epoxy in batches up to 176 lb. Variable-speed, 100-275 rpm motor eliminates splash back. Ergonomic handles ensure comfortable operation and protect mixer motor from dirt. Paddle has helical design that mixes batches from bottom up, preventing splash and keeping air from being sucked into material.

Read More »Grader provides accurate sizing of fruits and vegetables.

Precision Size Grader offers 95% efficiencies within 1/64 in. at capacities exceeding 10,000 lb/hr. Unit gently conveys product, minimizing bruising. Indicator system allows on-the-fly adjustability. Because last roller is fixed, each roller moves backwards as adjusting handle is turned at equal distance to create cumulative effect back to infeed roller. Low-maintenance design minimizes need for...

Read More »

Rotor Beater Mill produces powders in large quantity.

Model SR 300 processes materials with feed sizes up to 15 mm to fineness below 80 micron. Batch output is up to 30 L or 360 kg/hr in continuous mode. Mill achieves circumferential speed of 18,000 rpm. Circular screens, with hole diameters from 0.08-10 mm, determine final fineness of sample. Metal conidur filter provides for convenient handling. All parts in contact with sample are made of...

Read More »

Do You Have Unique Lifting Needs?

EZRig Cranes offers lifting solutions that are engineered for robust performance, providing the ultimate in portability. Designed for real-world lifting needs, our products are small and light with options and features that make them ideal for a broad range of applications. See our video to learn how an EZRig Crane can simplify your lifting requirements.

Read More »