Impeller / Propeller / Turbine - Agitators / Mixers

Coolant Mixer delivers accurate concentration of oil droplets.

Press Release Summary:

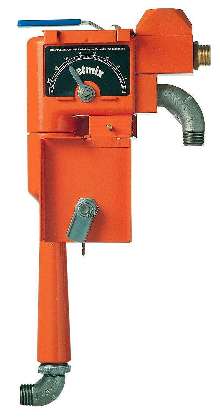

Jetmix® utilizes mixing-zone design, which creates strong shock waves of water vapor to break down coolant concentrate into highly homogenous emulsion of submicron size oil droplets. Resulting machining fluid provides stability, tramp oil rejection, and cutting-zone lubricity. Mixer is drum or wall mounted and connects to any tap water outlet providing 20-90 psi.

Original Press Release:

High-Performance Coolant Emulsion Mixer

GOSHEN, N.Y., Jan. 6, 2003 - Achieving the appropriate concentration level and size of oil droplets when mixing coolant concentrate and water impacts a number of important metalworking process characteristics, including cutting performance, tool life, sump life, and coolant consumption. The Jetmix® coolant mixer from Blaser Swisslube relies on a mixing-zone design that creates strong shock waves of water vapor to break down the coolant concentrate into a highly homogenous emulsion of sub-micron-size oil droplets. The result is a machining fluid characterized by exceptional stability, tramp oil rejection, and cutting-zone lubricity. The compact Jetmix coolant mixer is easy to operate. It is available for drum or wall mounting, and connects to any tap water outlet providing 20-90 psi. For more information, contact Randy Templin, Marketing Department, Blaser Swisslube Inc., 31 Hatfield Lane, Goshen, NY 10924. Call 845-294-3200; fax 845-294-3102; e-mail mailboxusa@blaser.com, or visit www.blaser.com. Producer of metalworking fluids The international Blaser Swisslube group manufactures coolant and oil formulations for all metal removal applications, emphasizing product designs that contribute to elevated cutting performance, long-term usage, and excellence in health, safety and ecology. In the US, Blaser products are manufactured by Goshen, N.Y.-based Blaser Swisslube Inc., active in North and South America through direct representation and factory trained resellers. Major coolant product lines include Blasocut (mineral-oil-based formulations) and Vasco (vegetable-oil-based) for all-purpose use, and Grindex (synthetic formulations) for grinding applications. Cutting-oil product lines include Blasomill (mineral oil base) and Vascomill (vegetable oil base).