OMAX to Tout Engineering Benefits of Abrasive Waterjet Technology at IMTS

KENT, Wash.Ã- – OMAX Corporation will highlight how the company’s abrasive waterjet technology is engineered to provide successful cutting solutions to the manufacturing industry at IMTS 2016. OMAX will have live cutting demonstrations in booth N-6228 to showcase how quickly their JetMachining Centers produce high precision parts from virtually any material. Visitors can watch 3D and...

Read More »

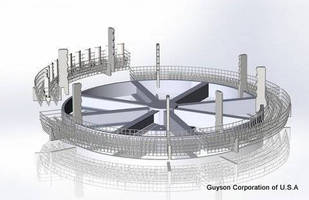

Guysons SP-10 Custom Grit Blaster for Batch Processing Gas Turbine Blades

When a major fortune 500 Aerospace company , who had built their reputation on being dependable , selected Guyson to design and build a custom grit blaster for batch processing gas turbine blades; our engineering team realized that this was something truly unique . Our customer was involved throughout the design of the system and was impressed with how we were able to completely blast the blades...

Read More »

Robotic Nozzle Cleaning Station reduces integration efforts.

With digital Ethernet communications, TOUGH GUN™ TT3E Reamer fosters integration into digital controls infrastructure. Design eliminates need for analog switch, which also reduces cabling requirements and reduces potential failure points. Also included, remote monitoring capabilities let companies oversee and troubleshoot I/O of each reamer function and its allowable parameters in real-time and...

Read More »Suction Blast Cabinets

Startus Technologies has an innovative Pro-Finish suction cabinets which cost less and are simpler than pressure cabinets. These suction cabinets blast continuously without the need to stop for media refills, and they simplify the use of multiple nozzles. The results are usually comparable to those achieved with a pressure system although production rates are not so high. When initial cost and...

Read More »

Reshoring in Metal Stamping

This white paper provides an overview into the reshoring of metal stamping and other manufacturing processes.

Read More »Schmidt Portable Abrasive Blasters

Stratus Technologies supplies and innovative Schmidt abrasive blasting systems that features efficient piping designed to provide the industry’s lowest pressure drop. For each drop in pressure of just 1 psi at the blast nozzle, a blasting system loses 1 1/2% in productivity, so minimizing pressure drop is important. Schmidt systems are low maintenance for reduced downtime. They’re designed...

Read More »Air Blast Equipment

Stratus Technologies carries an innovative and extensive line of Air blast equipment that can satisfy both specific and general customer needs.Ã- There are various options; Portable units, Blast rooms, Blast cabinets, and Automated Blast cabinets. They will help find the best and most cost effective solution for your production needs. Automated Barrel Blasters is designed to handle larger...

Read More »Tumblast Systems

Stratus Technologies supplies Gibson Tumble Blasters process multiple parts, ranging in size from small to medium, with a level of speed and efficiency unmatched by other types of equipment in a comparable price range. Gibson produces Tumble Blasters in six standard models with load capacities ranging up to 3,000 pounds or 24 cubic feet. Our smaller units, available with either wheel or air-blast...

Read More »

DURALUM-® Special White: Blasting for Purity VIDEO

Are you concerned about contaminants left behind when blasting or coating a sensitive work piece?Ã- Are you searching for a high purity, low iron, consistently controlled white aluminum oxide for your blasting or coating application? Please view our new video on blasting with DURALUMÃ-® Special White for high purity applications. http://www.washingtonmills.com/about/video/ About...

Read More »

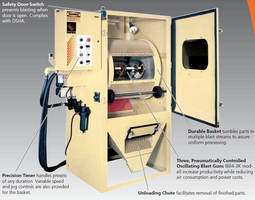

Three Key Benefits for Basket Blasters

Empire's BB2 and BB4 Basket Blasters automate cleaning, peening and finishing of small work-pieces. With certain types of parts, no other finishing method can compare to these heavy-duty production machines in terms of speed and quality results. Typical applications are for parts or items that may be rusty, or in need of cleaning, or where you need to achieve a required surface finish for...

Read More »

Robotic Blasting: Key Applications & Efficiencies

To compete in a hyper competitive global finishing market the use of robotics in air-blasting is quickly becoming the preferred method to reduce costs, increase productivity and improve product quality. Our experience has enabled Empire to design robotic blasting systems that meet the needs of today’s most demanding applications. Key Applications: Empire has custom engineered and built hundreds...

Read More »

Dies & Stamping Services with Over 25 Years of Experience

PDS is an established leader in progressive die stamping, with a reputation for providing precision and value that dates back more than half a century. Through extensive capabilities and a staff of seasoned professionals, we set the standard for quality, delivering flexible services that can meet the needs of the most challenging requirements. See our video to learn more.

Read More »