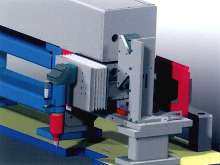

Laser Trimming Stations suit automated assembly equipment.

Laser trimming stations cut profiles into conveyed plastic components with production rates of one part each 3 seconds (laser cut requires 1.5 seconds). Stations utilize Coherent Diamond K150 sealed lasers, linear motor stages, and Delta Tau controller. Configured to operate automatically, they take commands and send status directly to main machine controller via digital interface. Up to 255...

Read More »

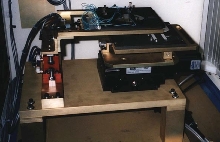

Laser Trim System offers lamp or diode pumped laser.

Autolase 2000 Nd:YAG laser resistor trim system features high speed galvanometer beam steering for fast cuts, CCTV magnified viewing of work area, and system control via Pentium PC and menu driven trim software. Measurement system provides for wide range of resistance and DC voltage ranges as well as easy connection to external instrumentation. Step and repeat handler/prober is available in sizes...

Read More »

Understanding Lights Out Manufacturing

This white paper gives an overview of understanding lights out manufacturing.

Read More »

Optimize Your Storage or Distribution Facility with Steel King Rack Solutions

Steel King racks are designed to meet seismic requirements in the most demanding conditions. Our durable storage products help your company save on maintenance costs. Check out our product video or download our Rack Planning eBook to learn more.

Read More »