Angle Grinder operates in harsh conditions.

Model R1000 Heavy Duty 4Ã-½ in. Angle Grinder features die-cast gearbox and 8 A motor, which allows grinder to operate in dusty, abusive jobsite conditions. Motor has auto-stop brushes that halt grinder's operation when brushes are worn, before they damage motor. Automatic safety clutch protects user from sudden kickback if wheel accidentally binds. Grinder includes spindle lock, 2-position...

Read More »Wiper Inserts promote long tool life.

Series ELUW Wiper Inserts, designed for high-end finishing, utilize 3-step projections for chip control. Best chip control is achieved in low-carbon alloy steel applications, including shafts and gears. Inserts feaure sharp cutting edge and wave edge, which contributes to stable chip control during copy turning.

Read More »

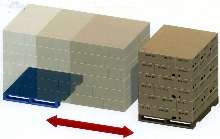

Load Transfer Equipment changes pallet types.

Load Transfer Product Line allows transfer of product to alternate load base for shipping or storage. Alternate load base includes pallet-to-pallet, pallet-to-sheet, or pallet-to-floor or truck deck. Fork lift driver places load onto receiving deck and pulls chord to start machine. After transfer, forklift driver can pick up load from any of 3 available sides.

Read More »

Splice Kits target telecom and electrical markets.

HYREDUCER and HYSPLICE Kits provide in-line reduction or splice of 2 conductors. They are pre-packaged with connector and length of heavy-duty black or clear heat shrink tubing that has passed Telcordia GR-347-CORE Abrasion and Cut Test. Inspection holes in connectors ensure conductor has been fully inserted. All connectors are UL listed.

Read More »

The Ultimate Guide to Packaging Automation Solutions

This ebook provides an in-depth guide to packaging automation solutions.

Read More »Bending System handles high/low production runs.

Usable for batch runs as small as 30 units, BendMaster handles components up to 88 lb. Product is controlled via single control system and is programmed using ToPs 600. Automation extension module can be used to program bending cell. Part geometries are defined once or can be taken over from ToPs programs. Bending process and part handling are generated automatically, and simulation allows...

Read More »

Multi-Parting Line Systems target plastics processors.

Multi-Parting Line (MPL) Systems double cavitation of standard single-face molds. They can be configured as turnkey systems with mold bases, hot runner systems, temperature controllers, and centering devices. Stack Mold Components enable system customization. Dual Mold Carrier enables MPL molding utilizing existing single-face molds. Tandem Molding employs 2 mold faces with staggered processes,...

Read More »Plasma Arc Cutter uses compressed air for fuel.

Air Force(TM) 625 cuts Ã-½ in. steel at 10 ipm using hand-held torch. It severs steel up to 7/8 in. thick and slices through thinner materials such as Ã-¼ in. steel at more than 60 ipm. Wind Tunnel TechnologyÃ-® helps prevent abrasive dust and metal particles from damaging internal components. When paired with engine drive, Air Force 625 draws about 30 primary A on 230 Vac line. Since...

Read More »

Viscometers are offered with high-shear spindles.

CAP Cone and Plate Viscometers are offered with spindles that provide shear rates from 10 sec-1 to 13,300 sec-1. Designed to test sample volumes of less than 1 mL, CAP 1000+ and CAP 2000+ Viscometers offer temperature control from 5 to 235Ã-

Read More »

CNC Lathes feature flat bed configuration.

MultiTurn 1000 and 2000 offer 13 in. swing x 25 in. center and 15 in. swing x 50 in. center, respectively. MultiTurn 3000 features 18 in. swing. All use GE Fanuc OiTB digital control package with 8.4 in. color TFT flat screen monitor. Ten horsepower spindle drive motor provides 3 spindle speed ranges, with speeds of 20-3,500 rpm on MultiTurn 1000 and 15-2,700 rpm on MultiTurn 2000. Cast iron...

Read More »Toolholding System has design that reduces runout.

Head Fitting System (HFS) toolholder design increases tool life by up to 3X. Face contact added to taper connection provides longitudinal positioning accuracy equal to one-piece tools and concentricity and changeover accuracy is less than 3 microns. Design consists of head, holder, and differential screw. Tool can be changed without presetting or adjustments, and defined release force enables...

Read More »

SEALTITE® Fittings and Cord Grips Offer Longer Lasting Protection

Anamet Electrical's 316 Stainless steel SEALTITE® fittings and UL-listed cord grips protect sensitive wiring components from fluids, corrosive contaminations, bumps, and abrasions with a steel core and liquid tight conduit jacket. Check out this video to learn more.

Read More »