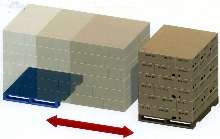

Load Transfer Equipment changes pallet types.

Press Release Summary:

Load Transfer Product Line allows transfer of product to alternate load base for shipping or storage. Alternate load base includes pallet-to-pallet, pallet-to-sheet, or pallet-to-floor or truck deck. Fork lift driver places load onto receiving deck and pulls chord to start machine. After transfer, forklift driver can pick up load from any of 3 available sides.

Load Transfer Product Line allows transfer of product to alternate load base for shipping or storage. Alternate load base includes pallet-to-pallet, pallet-to-sheet, or pallet-to-floor or truck deck. Fork lift driver places load onto receiving deck and pulls chord to start machine. After transfer, forklift driver can pick up load from any of 3 available sides.Original Press Release:

Columbia's Load Transfer Line Efficiently Changes Pallet Types

Columbia Machine's new Load Transfer Product Line allows plants to retain their plastic, Chep or expensive in-house pallets for use in their palletizing and production process by transferring their product to an alternate load base for shipping or storage. The alternate load base includes pallet-to-pallet, pallet-to-sheet, or pallet-to-floor or truck deck.

The load base transferring is a very simple process that starts with the fork lift driver placing a load from either of the two sides onto the receiving deck and pulling a chord to start the machine into motion. Once the transfer is complete the forklift driver can pick up the transferred load from any of the three available sides.

The Load Transfer product line from Columbia Machine includes models ranging from the basic stand-alone station to fully automatic versions that can be installed as an integrated part of larger systems.

For more than 40 years, Columbia Machine has manufactured high-level, floor-level, and robotic palletizers and accessories in the USA. All Columbia products are backed by 24-hour customer support and parts service.