Milling Chuck clamps with high force and accuracy.

Ultra-Lock provides clamping torque 30 to 60% greater than conventional milling chucks and has run-out accuracy within 5 microns at 100 mm from chuck's nose. Compact nose ring reduces interference, and collets accommodate multiple tooling sizes. Chuck is available in 5 sizes to handle cutting tools from 1/8 to 2 1/2 in. Options include high-speed machining version and coolant delivery systems.

Read More »

Universal Grinder provides precise grinding of small lots.

GE4-100 Select features solid box-type construction, and ribbed cast bed for rigidity and thermal stability. Wheelhead rotates from 90Ã-

Read More »

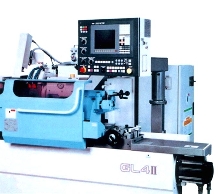

Cylindrical Grinder is programmable for variety of parts.

Model GL4 has box-type, ribbed foundation for rigidity and thermal stability. Hydrostatic/hydrodynamic STATÃ-® bearing technology, in wheel head, eliminates metal-to-metal contact. Grinding-specific control comes with pre-programmed cycles for plunge and traverse grinding. Floating plate mechanism supports both X and Z-axis ballscrews, and prevents transfer of run-out to table or wheel head...

Read More »

Horizontal Machining Center offers 5-axis machining.

Model FA630, with 40 hp, direct-drive, 50-taper spindle, provides infinitely variable speeds between 15 and 6000 rpm. It is also offered with 5000 rpm geared headstock for high-torque, low-speed applications. Boxway design allows FA630 to reach cutting and positioning speeds of 1417 ipm. Pressurized lubrication system rests loaded pallets on micro-thin 0.00012 in. film of lubricant. Spindle...

Read More »

An Introduction to Plastic Injection Molding

We developed this eBook with designers, engineers and purchasing specialists in mind. It is written to provide a basic understanding of plastic injection molding presses, processes and costs. Our goal is to make our customers more knowledgeable about what goes into making a plastic part.

Read More »

Horizontal Machining Center includes vertical pallet pool.

FA630 features 3-level, 15-station vertical pallet pool, which stocks enough work to support unmanned shift, enabling round-the-clock operation. It has boxway design with maximum rigidity for heavy-cutting applications. Pressurized lubrication system provides positioning and cutting speeds of 1417 ipm. Tools up to 33 lbs are exchanged in less than 2 seconds, with heaviest 60 lb tools taking just...

Read More »

Machining Center includes 204-tool magazine and software.

Model FA550 horizontal machining center, with stationary tool storage rack, accommodates up to 340 tools. Magazine handles tools up to 8.5 in. and 80 lbs. Tool gripper, driven by servo motor, travels at 80 ipm. OP Supporter software provides overview of tool magazine and confirms that right sub-programs and tools are ready for each job. Tool change speed is automatically adjusted according to...

Read More »

Milling Machine features fixed bed design.

HS-324 features dual-opposed spindle milling head with 2 separate spindles: 6000 rpm, 20 hp conventionally driven unit providing low end torque for roughing; and 30,000 rpm, 10 hp electrospindle for high speed finishing. Five axis capabilities are achieved by combining swiveling vertical spindle with rotary table built-in to stationary table surface. Rotary table is 40 in. dia and runs at 80 rpm...

Read More »

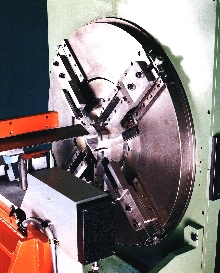

Cut-Off Machine features rotating tool technology.

Model RH 450 handles material diameters up to 4.500 in. Rotary head can be equipped with 2 or 4 carbide insert cut-off tools, producing accurate square cut ends without marking or deforming material being cut. Transfer arm immediately removes cut piece to secondary station for further operations such as chamfering and deburring.

Read More »

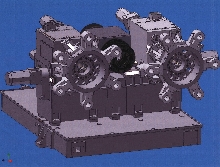

Turning Machine comes in bar capacities from 3.00 to 8.00 in.

The SC-654 4-axis horizontal turning machine has twin 12-station turrets, GE-Fanuc 18i-Series CNC control, digital AC servo drive systems, and 54 hp SIEMENS AC spindle drive. It is designed for high-production applications such as bearings, automotive transmission and drivetrain parts, and hydraulic cylinder components. With optional live tooling, tool/part gaging, and automated material...

Read More »

Grinding Machines offer 500 through 1600 mm wheel diameters.

Melchiorre ELC Series double side, fine grinding machines include ball screw and pressure cell down pressure system; in-process, direct part, contact sizing system; and pneumatically adjustable upper wheel swivel bearing. Rigid C frame machine base allows close tolerance work. All functions are programmed, stored and monitored via color monitor PLC. Part to part size and parallelism of 1 Ã-µ...

Read More »

Precision Machining Solutions with Over 25 Years of Experience

Quality, customer service, and unbeatable value are the hallmarks of Hogge Precision. Since 1989 we have built a reputation as the go-to precision machining source, servicing many demanding industries. For CNC machining and screw machining, there are few manufacturers that can match our capabilities and expertise. See our video to learn more.

Read More »