Toolholders enhance performance for small diameter tooling.

ColdSet(TM) toolholders employ SMAART(TM) technology making use of Shape Memory Alloys (SMAs). They use cold temperature process to trigger phase transformation in crystalline structure of alloy. Units dampen harmonics that generate chatter and have no moving parts, collets, or nosepieces to hamper balance repeatability. They are offered in standard sizes from .500 in. down to .125 in. with BT...

Read More »Tip Changer/Checker/Dressers suit robotic resistance welding.

Pneumatic tip changer automatically changes upper and lower tips. Cycle time on tip change is less than 25 sec. Tip checker electrically checks tip to ensure occurrance of full dress. It also provides for continuity check through robot and is able to provide alerts in case of improper or no dress. Tip dressers are available in pneumatic and electric Dual Head models, as well as electric tip...

Read More »

Winder incorporates Accu-Wind control system.

Model MS 103-LD PMC, with dual spindle design, winds continuous lengths of difficult profile products. Both spindles operate through common dancer system to minimize change-over from full to empty spool. Accu-Wind manages machine functions/winding patterns, insuring precise placement of successive layers while maintaining tension and pitch controls. Line speed is rated to 500 FPM, package width...

Read More »

Film Machine runs at high speeds.

Large, 4 meter, cast film line processes industrial pallet stretch-wrap film at speeds from 1,470 to 1,960 ft/min, with outputs between 5,500 and 6,200 lb/hour. Faster cycle times eliminate off-line rewinding for hand wrap, and single roll handling system simplifies winding logistics. Process control system incorporates automatic die-control software and provides management reporting and recipe...

Read More »

Nylon Fasteners & Rivets: How Environmental Factors Impact Extraction Force

To learn more about what can affect your nylon fastener's extraction force, and how to avoid adverse side effects, download this white paper now.

Read More »

Card Press suits print shops and short run applications.

Model 1826-3 plastic laminating press utilizes 18 x 26 in. aluminum platens, and produces up to 2640 plastic cards/hr. Self-contained package includes laminator, closed-loop cooling system, trays, polished lamination plates, and pads. Advanced Control Package provides storage of 5 recipes, temperature and pressure ramping, actual vs setpoint data display, and visual and audible alarms, including...

Read More »Load Port lets OEMs meet end-user 300 mm requirements.

FIXLOAD(TM) 6M load port offers fast wafer-access time and load port-to-FOUP interoperability. It is fully compliant to relevant SEMI standards and is completely backward compatible. Optional single connector interface provides communication to E84, carrier ID, and FixMAP(TM) mapping systems. OEMs can choose between either RS 232 serial, 50 pin digital I/O, Ethernet, or DeviceNet(TM) load...

Read More »

Turning Center offers live tooling and multitask machining.

HawkÃ-® TC-200M 8 in. CNC Turning Center combines digital vector servo-axis drives, digital Heidenhain X-axis linear scales, and live rotary tooling for round parts processing at Ã-

Read More »

Turning Center features 45-

Digital-featured HawkÃ-® TC-300 Turning Center offers large thru-hole bar stock capacity of 3.5 in., max turning swing of 26.8 in., turning dia of 16.6 in. and turning length of 39.9 in. Hydraulically actuated 12 in. chuck is powered by single-range, gearless spindle drive. Standard 3000 rpm spindle drive motor delivers full 60 MTDR hp. Digital scale feedback, standard on X-axis, delivers...

Read More »Turning Center utilizes digital control and drive technology.

HawkÃ-® TC-200CX is equipped with Siemens A2100Di digital controls, drives, and motors that include Profibus interface for I/O communications. It maintains positioning accuracy of Ã-

Read More »

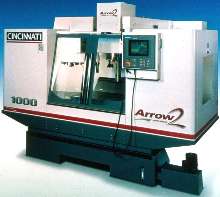

Machining Center offers Ultimate Performance(TM) package.

Arrow Series 2 VMC-1000 includes Profibus I/O interface technology and digital vector spindle drive that provides 30 hp (max), 25 hp MTDR. Spindle acceleration allows 40 series spindle to reach 8,000 rpm in 1.8 sec, while drive system provides constant torque, regardless of load. Process matching feedrates of 590 ipm are combined with traverse rates of up to 1,416 ipm. Operator convenience...

Read More »

Reduce Time to Market, Improve System Uptime with Dedicated Computing Medical Solutions

Embedded computing solutions from Dedicated Computing are designed to meet unique and specific requirements. As the preferred supplier to leading healthcare OEMs, the Dedicated Computing team of expert engineers gets your product out to the market faster while helping your company avoid costly validation and verification steps. Check out our video to learn more.

Read More »