Machining Center offers Ultimate Performance(TM) package.

Share:

Press Release Summary:

Arrow Series 2 VMC-1000 includes Profibus I/O interface technology and digital vector spindle drive that provides 30 hp (max), 25 hp MTDR. Spindle acceleration allows 40 series spindle to reach 8,000 rpm in 1.8 sec, while drive system provides constant torque, regardless of load. Process matching feedrates of 590 ipm are combined with traverse rates of up to 1,416 ipm. Operator convenience features include high intensity lighting and end panel windows.

Original Press Release:

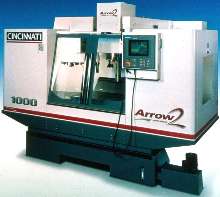

Arrow Series 2 VMC-1000 from Cincinnati Machine, on Display at IMTS, Defines Ultimate Performance(TM) Technology

CINCINNATI, OH (September 4, 2002) -The new Arrow Series 2 VMC-1000, offering increased power and spindle acceleration, enhanced rapid traverse and acc/dec performance, and fast axis drive, can be seen in full operation at Cincinnati's IMTS 2002 Booth #8101.

The VMC-1000's all-new Ultimate Performance(TM) package, which includes the state-of-the-art Profibus I/O interface technology as standard equipment, reduces wire terminations, improves safety and simplifies maintenance. Tested and proven, the components are installed on more than 3 million machines worldwide.

The digital vector spindle drive provides 30 Hp Max (22kW), 25 Hp MTDR. Improved spindle acceleration allows the 40 series spindle to reach 8,000 rpm in just 1.8 seconds. The drive system provides constant torque regardless of load.

Process matching feedrates of 590 ipm (15,000 mm/min) are combined with rapid traverse rates up to 1,416 ipm (36 m/min). The acc/dec rates are increased up to 70 percent.

Enhanced operator convenience features include high intensity lighting and end panel windows for increased visibility within the machining area. In addition, an integral workstation tray is incorporated into the control station.

The Arrow Series 2 VMC-1000 will be on display at IMTS with the optional GE Fanuc 21iB CNC. This new easy-to-learn and easy-to-use CNC control is ideal for shops that must start cutting faster from the outset and ensures that operators spend more time cutting than learning complex control systems.

The entire new Arrow Series 2 line - comprised of the VMC-500, VMC-750, VMC-1000 and VMC-1250C - are some of the most reliable, accurate and user-friendly vertical machining centers in today's marketplace.

Cincinnati Machine is a leading global manufacturer and supplier of CNC machine tools, such as turning centers, vertical machining centers, horizontal machining centers/cells, 5-axis machining centers, universal machining centers, profilers, routers and composite processing equipment. Additionally. Cincinnati PLUS(TM) provides the most comprehensive package of service and support available in the industry today. Industries served include aerospace, heavy equipment, fluid power and automotive, as well as small job shops.

To find out more about the Arrow Series 2 VMC-1000 Ultimate Performance Technology, visit IMTS 2002 Booth #8101 to see it in operation, call 1-877-CINMACH (246-6224), fax us at 513-752-9800, or visit our web site at www.CinMach.com.