Vertical Machining Center employs precision components.

Suited for mixed volume, short-run operations as well as dedicated high-volume applications, D Series VMCs provide 40.2 (X) x 20.1 (Y) x 25.2 in. (Z) work envelope and 48 x 18.1 in. table work surface. Machines feature 11 x 9 ft footprint and rapid traverse rates of 1,181 ipm. Other features include automatic tool changer; cast mono-block bed design (D 1000); GE Fanuc 21i control, and...

Read More »

CNC Turning Center simultaneously machines 1 or 2 parts.

Capable of simultaneous or independent machining, Nakamura-Tome WTW-150 employs twin spindles and 4 turrets. It can turn complex, precision parts completely in one setup. Machining flexibility is provided via independent slides, 13 controlled axes, equal left and right machining, and 48 stations of flexible tooling. Dual FANUC CNCs allow independent programming of each spindle, while polygonal...

Read More »Gang Tool Lathe offers small parts turning.

Prodigy GT-27 Single Spindle Lathe features polymer composite base that resists oxidants, thermal distortion, and vibration. Precision is achieved through incorporation of non-heat generating collet closers, absence of turret, and standard third indexing axis. Since lathe can index in 1Ã-

Read More »

Thread Grinder employs linear motors on linear ways.

Full helix thread grinder, model GS:TE-LM, allows operators to grind threads, splines, key slots, rings, and other forms on one machine in one setup. It also enables users to optimize dress and grind process by monitoring acoustical emissions. Machine automatically corrects wheel forms for helical path interference or generates forms using standard plated wheels. Product incorporates tenth-micron...

Read More »

Epoxy Crusher Backing Solutions for Construction Aggregate & Ore Mining Applications

This white paper provides a guide to epoxy crusher backing solutions for construction aggregates and ore mining applications.

Read More »

Rod Cylinder Slides come in 120 unique variations.

Tested and validated for max load at over 200 million linear inches of travel, RCS series includes choice of linear ball and composite bearing models in 5 bore sizes from 20-50 mm. Stroke lengths for each size are available in 1 in. increments up to 12 in. Products feature ISO style repairable cylinders with integral air cushions and dowel pin locating holes on tooling plate and slide body. On...

Read More »

Mills suit roughing, semi-finishing, and finish machining.

ValMILL(TM) V490 Series square-shoulder face mills have 90Ã-

Read More »

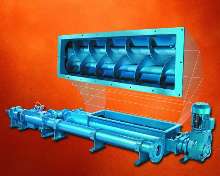

Reduction Units offer optimized cutter combinations.

Featuring one-piece flange housing and quick-change cutter cartridge, Series 4 Annihilator(TM) Grinders are twin-shaft solids reduction units suited for industrial and municipal applications. Equipped with counter-rotating, intermeshing cutters and spacer cutters, grinders protect downstream equipment from being plugged or damaged from large solids.

Read More »

Wire EDM Machine handles micro-miniature machining jobs.

Horizontal Model UPJ-2 can automatically thread 0.00078 in. wire through 0.0027 in. diameter start hole with 0.0059 in. pitch. Machine is enclosed within Thermal Guard(TM) temperature system, which helps control temperature inside covers to within 1Ã-

Read More »Bander and sleeve labeler can run on same conveyor line.

Continuous-motion, tamper-evident, banding machine, Model EZ-100 bands caps up to 69 mm dia and is capable of speeds to 150 bottles/min. Continuous-motion, full-body sleeving machine, Model EZ-130 can sleeve up to 80 mm dia with speed capabilities dependent upon width and length of sleeve. Each machine can process sleeves or bands with minimal changeover. Both can run side by side on same...

Read More »

Splicing Options facilitate changing of conveyor belts.

Plastic clipper and stainless steel clipper belt splicing options enable users to change belts on conveyors. Belts outfitted with said options can be replaced on tight-fitting conveyors or conveyors buried in machines by removing one pin. Installation is accomplished by wrapping belt around conveyor, splicing belt together in interlocking grooves, and securing it with one pin. Both clippers do...

Read More »

Cut and Bevel Pipe up to 63" Diameter with a Single Lightweight, Portable Machine

CS Unitec is a leader in power tools designed for industrial applications, with products that set the standard for robust performance and industry-leading reliability. Adding to our long list of innovation is a new line of pipe cutting machines. For cutting and beveling pipe up to 2" in thickness and diameters from 12" to 63", no other cutting system comes close. See our video to learn more.

Read More »