Manufacturing Systems feature PC-based machine control.

Flexsys(TM) automated manufacturing systems accommodate multiple process and assembly operations on one automated platform, and can be scaled up or reconfigured. Available models include Flexsys(TM) 1000 for semi-automated production and Flexsys(TM) 2000 for fully automated assembly and processing. Flexsys(TM) 3000 high-speed die bonder provides epoxy stamping to 50 microns, and Flexsys(TM) 4000...

Read More »

Machining Performer completes workpieces in 2 operations.

Integrex e-1060V combines vertical spindle with 50 hp turning table which accepts 31.5 in. dia or 31.5 in. square pallets. Its 600 rpm table has 0.0001 deg indexing increment. Maximum part machining diameter is 47.2 in., and maximum swing is 59 in. Its 10,000 rpm milling spindle provides 339 lb-ft of torque, and B-axis movement has 150 deg angular displacement. X, Y, and Z Axis strokes are 60,...

Read More »Fiber Cabinet holds up to 216 fibers.

Rack-mounted HRC suite, for high density applications such as Fiber-in-the-Metro (FITM) and Fiber-to-the-Business (FTTB), has bend radius controls at all exit ports, strain relief protection, and space for easy access to individual adapters and assemblies. Cabinet can be configured for variety of installation approaches, from pre-terminated to splicing on frame, while retaining maximum rack...

Read More »

Endforming Machine loads manually and endforms automatically.

Single-station Model LS-38S endforms tubes from 1/4 to 1 1/2 in. diameters, with swage lengths through 2.5 in. It delivers 8 tons of force to reduce, expand, flare, and bead ferrous and nonferrous tubes of almost any length. Tool changing is accomplished by removing 4 screws to remove clamp set, and one screw to remove forming tool.

Read More »

How EDM Controls Ensure Aerospace Validated Processes

Download this white paper to learn more about how wire EDM systems are used to validate aerospace manufacturing processes.

Read More »

Die Grinder incorporates spindle lock.

Model GE700 variable speed, 2 in. die grinder requires only one wrench on its hardened and ground 1/4 in. collet. Extended spindle ideal allows for operation in confined areas, and auto-stop carbon brushes prevent motor damage. Grinder has no-load speed of 7,000 to 27,000 rpm, and is rated at 6.2 amps, 710 watts. Power switch is located on top of tool.

Read More »

Machining Centers produce die, mold and precision parts.

Bridge-type HSM 400 is suitable for wet, dry, or graphite machining in tool and moldmaking industry. It has 7-position automatic pallet changer, tool magazines with choices of 18, 36, or 68 tools, and laser measurement system that monitors lengths and radii of tooling. Widely spaced guideways withstand forces of high speed machining. Spindle motors are liquid cooled with hybrid ceramic ball...

Read More »

Bimetal Saw Blade outlasts carbon steel ten times over.

Model 3861 Sandflex(R) NF(TM) bimetal bandsaw blade lasts 8 to 10 times as long as common milled carbon steel blades when sawing wood, plastics, and metals from foundry metals through alloy steels. Bimetal blade has high speed steel teeth beam-welded to spring steel back. Suitable for job shops and tool rooms, blades are available in sizes from 1/4 to 1 in. with 3 to 24 teeth-per-inch pitch.

Read More »

Turning Center features dual spindles.

TL-25 lathe allows turning of double-ended parts in single setup on one machine. It has 30 hp vector-drive main spindle with 10 in. chuck, and 8 hp sub-spindle with 5 in. chuck. Main spindle provides speeds to 3,400 rpm, and sub-spindle provides speeds to 4,000 rpm. Standard 12-station tool turret holds 6 VDI 40 tools and 6 bolt-on tools. Live tooling and full C-axis are optional.

Read More »

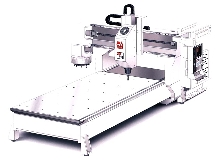

Gantry Router doubles as milling machine.

GR-510 offers travels of 120 x 60 x 10 in. (X,Y,Z) and 40-taper milling head. It includes 10,000 rpm spindle with 15 hp vector drive system. Automatic 10-pocket tool changer is standard. Machine's 5 x 10 ft fixed table provides support for large or heavy workpieces. CNC accepts ISO standard G-code and is compatible with major CAM systems. Built-in graphic dry-run mode allows operator to check...

Read More »

Machining Center provides drilling, tapping, and milling.

Mill Drill Center offers 12 x 10 x 12 in. work cube and 15,000 rpm 40-taper spindle, powered by 15 hp vector drive system. Ballscrews and high-torque servo motors on all axes provide rapids to 2,400 ipm and accelerations to 0.8 G. Automatic tool changer stores up to 20 tools and changes them in 1.5 seconds. Dual fixture stations allow operators to load and unload parts on one fixture while...

Read More »

ISO-Certified J&D Tube Benders Delivers Rapid Tubeline Fabrication Services

J&D Tube Benders' laser cutting and machining services provide accurate and complex features on tubes of all shapes and sizes. Check out the video to learn more!

Read More »