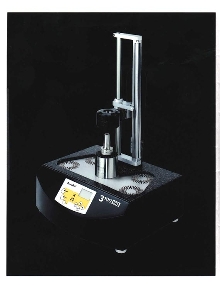

Toolholding System offers heat protection.

ISG 3100 multi-station ThermoGrip(R) can handle tools up to 50 mm dia. Ergonomically enhanced design eases operator use. Localized electromagnetic field heats clamping area in less than 10 sec, reducing heat transfer through chuck body and shank. Heat transfer canisters protect operator. Thermic clamping can be performed with drills, end mills, reamers, taps, and combination tools as well as Bilz...

Read More »

Abrasive Belt handles heavy grinding.

SK847 heavy-duty ceramic grain abrasive has extremely tough backing that performs well under severe grinding applications like heavy gate removal and power-assisted applications. Belt is top sized with added self-lubricating grinding layer that reduces heat during grinding process in heat sensitive applications. Problems of glazing, loading, and stripping on belts are also eliminated. It has good...

Read More »

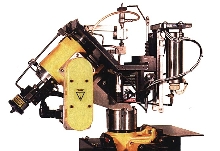

Bevel Head provides cuts for 3 and 5 axis applications.

Waterjet Bevel Head is for use with Vision NT CNC Windows(R)-based cutting machine controller. It allows for contour or straightedge beveling in flat-sheet material at any angle from -90 to +90 deg A-axis and -360 to +360 deg C-axis rotation. Bevel head features 0.005 in. total TIR at nozzle tip, 0.1 deg accuracy per axis, and 0.05 total repeatability per axis.

Read More »

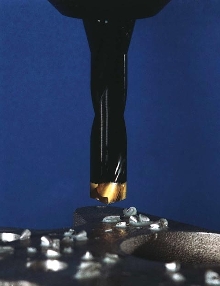

Drill matches brazed drill precision.

CrownLoc(TM) allows users to drill different diameters using same drill body. It features precision-ground interface of interlocking V-grooves to ensure repeated positioning of each crown. Cutting edges are produced by injection-molding carbide substrate, producing homogenous tungsten carbide. Double coolant holes through each crown permit high volume of coolant to reach cutting edge. Crowns are...

Read More »

Epoxy Crusher Backing Solutions for Construction Aggregate & Ore Mining Applications

This white paper provides a guide to epoxy crusher backing solutions for construction aggregates and ore mining applications.

Read More »

Angle Grinder offers tool-less wheel changes.

WE14-150 Plus with Vario-Constamatic full-wave electronic speed control, maintains constant speed while operating during maximum load and no-load conditions. It is rated at 1,400 watts, and operates at 6,000 to 9,000 rpm with 12.0 A motor. Maximum wheel diameter is 6 in. Grinder includes 2-position side handle, S-automatic safety clutch, winding protection grid, and thermal overload protection.

Read More »

Water Jet Lance can dump pressure in 2 ways.

NCG10-286DT dual-trigger water jet lance has quick-change cartridge seal to allow users to rebuild lance in under 1 minute. Rated for pressures to 10,000 psi and flows to 25 gpm, lance requires pressure on both triggers to actuate flow of water. Operator can immediately dump pressure by releasing either trigger or by pushing the trigger forward. It requires 8 to 12 pounds of trigger pressure, and...

Read More »

Plasma Cutter offers short repositioning time.

Aviator XLT, with FastCAM automatic nesting software, combines liquid-cooled plasma system with Burny 1250 CNC control to produce precision cutting of 12 ga steel at 250 ipm or 1/4 in. stainless at 100 ipm. Traverse speed is 500 ipm and vertical-lift speed of C&G AVC Plus plasma torch lifter 150 ipm. Welded, tubular-steel frame supports integrated 6 x 12 ft down-draft cutting table. Pneumatic air...

Read More »

Shrink-Fit Tool Holders include DIN designs.

HSK tool holders utilize Form A shanks that conform to DIN 69882 Standard. They are coolant-through holders with axial adjustment screws. Production balancing is standard and dynamic balancing is optional. Shrink-fit holders are offered in inch and metric bore sizes in USA and DIN designs. Standard, extended, and extra-extended length sizes in CAT 40 and 50 V-flange shanks are available. Tapers...

Read More »

Plasma Cutting System prevents tip failure.

CUTMASTER(TM) 75, a 60 amp, 7/8 inch system, is equipped with fold-back circuit, which prevents tip failure when tip touches work at high-output current levels. Cut is virtually dross-free with minimum of bevel across full range of metal thicknesses. System stands up to rough handling, metal dust, shop grime, and difficult cutting conditions.

Read More »

Holding Assemblies are offered in hundreds of shapes and sizes.

Permanent Magnetic Holding Assemblies are designed for positioning, stabilizing, holding, and feeding materials, parts, and scrap. Standard configurations and sizes include Ceramic, Alnico, and Rare Earth magnets. Watertight and high-temperature units are available. Assemblies are used in metal product manufacturing, including workholding and spot-welding.

Read More »

Material Handling Solutions from Global Leader in Rubber & Urethane Power Transmission

Megadyne's QST polyurethane timing belts take up less space and guarantee a lower noise level than chain and other traditional material handling belts. Check out our video to learn more.

Read More »