Automatic Grease Dispensers reduce downtime.

Automatic grease dispensers deliver precise amount of grease to critical machine parts while machinery is running. Units provide variable feed rates lasting from 1-12 months and feed up to 6 lubrication points. Dispensers provide precise metering of lubricant in remote areas up to 30 ft and are equipped with electro-chemical or electro-mechanical drives.

Read More »

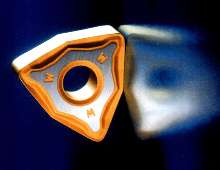

Wiper Inserts suit high-feed finishing applications.

Negative C- and D-style pin-type, double-sided inserts are offered in chipbreaker M3 for general finishing purposes; or MF2 for high-accuracy applications. Both come in grades TP1000 or TP2000. Positive W- and T-style inserts are offered in chipbreaker F1 for high-feed finishing with low cutting forces. T-style comes in grade TP100 or TP2000 and W-style comes in TP2000 only. Geometry WZ is...

Read More »

Profile Grinding System suits lean, cellular production.

Blohm Profimat MC traveling-column machine is capable of multi-axis grinding in 2,000 mm-wide footprint. Access from front and back allows units to be set side by side. Modular platform concept includes GE Fanuc 18i CNC control, machine bed, column, wheelhead, and machine table. Linear guideways in all axes consist of 6-row ball and 4-row roller bearing systems that provide stick-slip free...

Read More »

Cylindrical Grinder tackles short runs and mixed lots.

Model S151cnc features modular design and digital control and drive systems. Swing diameter is 350 mm, between-centers grinding length is 200 mm, and chuck capacity is 150 kg. Turret head arrangement presents 2 grinding spindles for rough and finish grinding in same set-up. Spindle configuration is ID/ID or combination ID/OD for universal applications. Grinder features max spindle diameter of 170...

Read More »

A Guide to Preventive Maintenance & Refurbishment of Your Tablet Press

Check out this guide to keeping your tablet press in good working order.

Read More »

Fineblanking/Forming Press facilitates complex part production.

Equipped with 1250 mm bed and PC-based control, CNC HLT-1250 triple-acting hydraulic fineblanking and forming press offers cutting force of 4,000 kN. It has 2 additional 500 kN pressure pads integrated in press table or tool change plate and accepts compound and progressive tools. Upper die clamping area measures 1250 x 900 mm. Product provides ram opening/closing speed of 200 mm/sec, blanking...

Read More »Cut-Off Wheels offer long life.

Zip(TM) Wheels produce faster cuts to yield cooler material, even after numerous cuts, and 50% longer life over previous models. Extra-thin design minimizes cutting resistance. Applications include steel and stainless steel.

Read More »

Material Forming System is offered with electric feed.

Model E2H-350 press offers high-tensile cast-iron components, for vibration dampening, and Quick Access Slide Mechanism that provides instant access to die area plus ability to release die jams. Hydrostatic 8-point gibbing provides stiffness. Alternative Slide Motion option affords reduced slide velocity in working angle of stroke with fast return velocity in non-working portion of stroke....

Read More »

Lubrication Devices suit hygienically clean applications.

Gas and motorized G-Power and M-Power single-point lubricators connect to existing grease or lubrication fittings to apply lubricant to bearings, chains, guideways, gears, and seals. They dispense precise amount of grease over set period of time. Available in 3 models, G-Power gas lubricators suit high humidity/corrosion applications. M-Power motorized lubricators offer reusable drive motors,...

Read More »

Label Holder solves problems in wash down areas.

Model B30 Bottom Load Label Holder eliminates saturation and bleeding of labels caused by washdown solutions entering through open top of top-load label holders. One-piece, sealed-at-the-top design shields labels from water, cleaning fluids, and dirt. Soft, integral bead under clear front window provides added grip to hold labels in place. Bottom opening allows promotional signage to hang below...

Read More »

Extrusion/Materials Package offers 1-step pipe production.

Extrusion Package utilizes silane liquid blend, which is absorbed on porous resin during material feeding and introduced with main resin to extruder, allowing for continuous formation of extruded pipe. System includes 3-component drying system, 4-component dosing station, 75 mm 32:1 air cooled extruder with feedscrew and 1.5 L/D grooved feed section, 25 ft vacuum tank, 25 ft spray tank,...

Read More »

ISO-Certified Plastic Injection Molding from Rodon

The Rodon Group is a proven leader in high-volume, close tolerance injection molding. We offer globally competitive, innovative manufacturing solutions for a broad range of industries. Check out our video to learn more.

Read More »