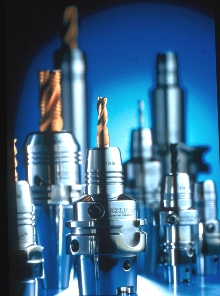

Toolholders handle repeated thermal clamping.

ThermoGripÃ-® shrink-fit toolholders can be used with carbide and high-speed steel cutting tools. Made from heat resistant tool steel with hardening process, they maintain high concentricity and elasticity even after large number of shrinking cycles. Internal geometry provides maximum gripping force with near-perfect concentricity. Toolholders and extensions are available for any spindle...

Read More »

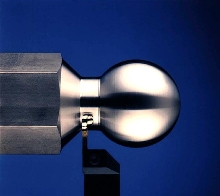

Drill and Tap Holders have sealed ball-lock design.

Ball-lock drive technology provides fingertip control and tool changes as fast as 5 seconds. Six steel balls are mounted in spindle to retain and drive close-center drill holder. Balls fit into machined detents spaced 60Ã-

Read More »

Tool Holders suit Tornos multiple-spindle screw machines.

Floating Tornos shave tool holders are manufactured from high-alloy steel for strength and rigidity. Tools compensate for machine spindle and indexing movements, and eliminate OD size and concentricity variations. They improve knurling and threading operations as well as surface finish. Design features include key that prevents chips from packing into keyway. One calibrated screw provides zero...

Read More »

Toolholders use concentricity to hold tools.

SK, BT, and HSK toolholders are manufactured with hydraulic chucks in extended, and slim extended lengths from 63.5 to 200 mm. Guaranteed run-out of 0.0012 in. is maintained, and clamping forces are rated to 23,000 lbs. Shank-holding system with internal piston forces sleeve around cutting tool shank. Clamping area remains almost dry and high torque transmission is accomplished via metal to metal...

Read More »

Distillation 101: A Guide to Distillation and Separation Technologies

Distillation is a separation unit operation that involves multiple countercurrent-stage steps, separating two or more volatile components. This results in the contact of liquid and vapor most generally in counterflow. Distillation 101: A Guide to Distillation and Separation Technologies provides an in-depth look at everything you need to know about distillation, including: Design procedures Equipment components Applications

Read More »

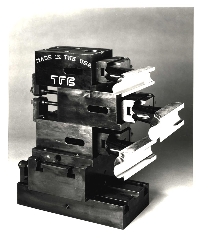

Die Holder fits stacked tooling sets.

Available for any size or brand of rotary bender with stacked tooling for 2 to 3 sets of tools, Model TFB wiper device is easily adjusted to properly fit different radius bend dies. Each wiper die can be adjusted to locate wiper with correct amount of angle in relation to tube or rake. Wiper die support helps prevent tube wrinkling and prolongs life of dies. Automatic lubrication to each wiper is...

Read More »

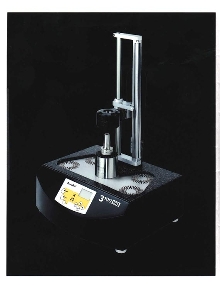

Toolholding System offers heat protection.

ISG 3100 multi-station ThermoGrip(R) can handle tools up to 50 mm dia. Ergonomically enhanced design eases operator use. Localized electromagnetic field heats clamping area in less than 10 sec, reducing heat transfer through chuck body and shank. Heat transfer canisters protect operator. Thermic clamping can be performed with drills, end mills, reamers, taps, and combination tools as well as Bilz...

Read More »

Shrink-Fit Tool Holders include DIN designs.

HSK tool holders utilize Form A shanks that conform to DIN 69882 Standard. They are coolant-through holders with axial adjustment screws. Production balancing is standard and dynamic balancing is optional. Shrink-fit holders are offered in inch and metric bore sizes in USA and DIN designs. Standard, extended, and extra-extended length sizes in CAT 40 and 50 V-flange shanks are available. Tapers...

Read More »

Holding Assemblies are offered in hundreds of shapes and sizes.

Permanent Magnetic Holding Assemblies are designed for positioning, stabilizing, holding, and feeding materials, parts, and scrap. Standard configurations and sizes include Ceramic, Alnico, and Rare Earth magnets. Watertight and high-temperature units are available. Assemblies are used in metal product manufacturing, including workholding and spot-welding.

Read More »

Tool Holders suit multi-spindle screw machines.

Tornos form tool holders are manufactured from high-alloy steel, and offers key that prevents chips from packing into keyway and affecting taper mechanism. One calibrated screw in holder design provides zero backlash taper adjustment. Holders have 8 deg rake angle, and accept 5/8 in. dovetail tooling. Two holder designs, models 31-21 and 31-22, are available to accommodate both sides of spindle.

Read More »

Toolholding System provides rigid, stable contact surface.

MDT(TM) uses single toolholder and insert for turning, profiling, and grooving in both axial and radial directions. For complex components with many grooves and profiles, one tool replaces several conventional tools for simplified tool handling and stocking requirements. It can handle wide variety of face machining operations and has PCBN inserts for tougher materials and small diameter boring...

Read More »

Precision Machining Solutions with Over 25 Years of Experience

Quality, customer service, and unbeatable value are the hallmarks of Hogge Precision. Since 1989 we have built a reputation as the go-to precision machining source, servicing many demanding industries. For CNC machining and screw machining, there are few manufacturers that can match our capabilities and expertise. See our video to learn more.

Read More »