Toolholding System offers heat protection.

Press Release Summary:

ISG 3100 multi-station ThermoGrip(R) can handle tools up to 50 mm dia. Ergonomically enhanced design eases operator use. Localized electromagnetic field heats clamping area in less than 10 sec, reducing heat transfer through chuck body and shank. Heat transfer canisters protect operator. Thermic clamping can be performed with drills, end mills, reamers, taps, and combination tools as well as Bilz tap adapters, and torque adapters.

ISG 3100 multi-station ThermoGrip(R) can handle tools up to 50 mm dia. Ergonomically enhanced design eases operator use. Localized electromagnetic field heats clamping area in less than 10 sec, reducing heat transfer through chuck body and shank. Heat transfer canisters protect operator. Thermic clamping can be performed with drills, end mills, reamers, taps, and combination tools as well as Bilz tap adapters, and torque adapters.Original Press Release:

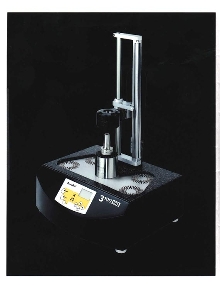

Bilz Introduces New Thermogrip(R) ISG 3100 Multi-Station Toolholding System

April 24, 2002 -- Bilz Tool Company (Elk Grove Village, Ill.) has introduced its newest generation ThermoGrip(R) toolholding system - the ISG 3100. The ISG 3100 multi-station system improves upon earlier ThermoGrip generations with an ergonomically enhanced design to ease operator use.

Other improvements include new and improved software allowing for easier shrink/unshrink transitions between HSS and carbide toolholders. In addition, the ISG 3100 has expanded its toolholder capacity and can now handle tools up to 50 mm in diameter.

Like its predecessor, the ThermoGrip ISG 3100 provides a user-friendly control panel that guides the operator through the program with a menu-driven alphanumeric display. In the manual mode, all parameters can be input and checked on the display. Or, all settings can be chosen automatically by the integrated processor, which will select the power and duration of the heating process depending on the input data supplied.

Bilz ThermoGrip systems makes shrinking practical for many production applications through the use of a high-energy induction heating coil. The localized nature of the electromagnetic field heats the clamping area of the toolholder in less than 10 seconds, reducing heat transfer through the rest of the chuck body and shank. Where conventional systems heat the tool clamping unit to the point that the entire holder is too hot to touch, ThermoGrip provides heat transfer canisters to protect the operator. This allows tools to be handled and changed in just two to three minutes, improving safety and shortening the cycle time of tool setting operations.

The system is also highly versatile, as thermic clamping can be performed with drills, end mills, reamers, taps and combination tools as well as Bilz tap adapters and torque adapters, which are ideal for clamping difficult to hold carbide taps. The company also offers tool clamping units in all popular shank styles, including HSK, V-Flange, DIN and others.

ThermoGrip clamping units provide better performance at about half the cost of first generation units on the market. Additional information on Bilz quick-change toolholders and the ThermoGrip thermic tool clamping system can be obtained free on request from Bilz Tool Company, Inc., 1351 Brummel Ave., Elk Grove Village, Illinois 60007. Tel: (800) 227-5460, Fax: (800) 937-7752. Or, visit us on the web at www.bilz.com.

Bilz Tool Co., Inc., part of the Leitz Metalworking Technology Group of companies (Oberkochen, Germany), manufactures a premier line of high technology tool holders for drilling, tapping and reaming.