Indoor/Outdoor Sign System comes in range of sizes, styles.

In addition to offering flexibility to apply vinyl graphics to existing solid backer panel, FoldingFrame is also available with one front-loading DisplayFrame or SekureFrame that can hold up to 22 x 28 in. poster-size graphics. One-piece hinge opens to 47Ã-

Read More »MSC Industrial Direct Co., Inc. Exhibits New Customer Solutions at EASTEC

Melville, New York, March 31, 2009 - MSC Industrial Direct Co., Inc., the country's leading distributor of metalworking and maintenance, repair and operation supplies, will showcase a variety of customer solutions at EASTEC 2009. MSC will be located in booth 5323 from May 19 - 21 at the Eastern States Exposition Grounds in West Springfield, Massachusetts. Visitors to booth 5323 will have an...

Read More »

Hydraulic Toolholders require no intermediate sleeves.

TENDO hydraulic expansion toolholders clamp different types of cutting tools with cylindrical shanks directly in toolholder without using intermediate sleeves. Tools with different shanks are held with concentricity of less than 0.003 mm. System also absorbs vibrations inherent in cutting or grinding processes, with T.I.R. accuracy and repeatability of less than 3 microns. Completely closed...

Read More »

REGO-FIX-® Features Revolutionary Toolholding Solutions at EASTEC

Indianapolis, Indiana, March 9, 2009 - REGO-FIXÃ-® will display an extensive lineup of Swiss quality toolholding solutions at EASTEC 2009. The company's revolutionary powRgrip PG system will be among the many innovations featured in booth 5449 from May 19 - 21 at the Eastern States Exposition Grounds in West Springfield, Massachusetts. REGO-FIX's powRgrip PG system uses a toolholder and...

Read More »

Collet Chucks operate on CNC lathes and turning centers.

Offering gripping capacities from 1/64-4 in. diameter, Pullback CNC Collet Chucks are guaranteed to run within 0.0003 in. TIR. All chuck components, except drawtube connector, are hardened to Rc 61-63 for rigidity. Available in special and quick-change styles, low-profile chucks are balanced for high-speed operation and are suitable for lathe, milling machine, grinding, and mill turning...

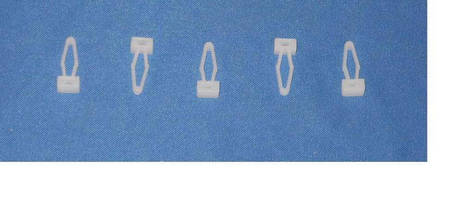

Read More »Pressure Hold Cable Tie Holder is RoHS compliant.

Accepting WIT-18 thru -50 and QTE-18 thru -50 cable ties, FTH-3A-01 pressure hold cable tie holder allows for preassembly of cable tie into holder because it holds it in place. RoHS compliant unit provides pressure hold onto cable tie.

Read More »

Richco, Inc. Releases FTH-39 Cable Tie Holder

MORTON GROVE, IL - February 25, 2009 - Richco, Inc. is delighted to announce the release of its new cable tie holder, the FTH-39. The panel fastener and tie holder are combined in one product, and the low profile head design saves space. The FTH-39 allows for the preassembly of cable ties and holds them in place after preassembly. The FTH-39 is RoHS compliant. To review the FTH-39 or other cable...

Read More »

The Powerhouse of Hydraulic Expansion Toolholders Is the TENDO-ES

The SCHUNK TENDO-ES, is an extremely short hydraulic expansion toolholder, which allows the tool to be clamped directly in the mounting taper. This way, the tool shank is supported via the spindle. The result is the highest holding forces for transferable high torques and a great deal of additional space in the machining area. The TENDOS-ES L1 is 26.0 mm, has a run-out accuracy of less than 0.003...

Read More »Support Grid fits any thin, low-profile air filter assembly.

Featuring smooth surface for sliding in and out of equipment, Uni-Grid Support prevents filter media from sagging beyond frame, keeping media within overall filter assembly thickness profile, making it beneficial for applications where filter is installed near fan intake area. RoHS compliant unit meets standards and classifications including UL 94 HF-1, ATCA, UL 900 Class 2, CE, Telcordia, NEBS...

Read More »

Techniks Certified ER and TG Toolholders

Techniks ER and TG toolholders are certified to meet the highest standards for T.I.R., balance, and taper accuracy. Overall rigidity and T.I.R. is improved even more by Techniks special Power Coat nut, which holds 75% tighter than standard nuts. The combination of an extremely accurate tool holder body and the holding power of the Power Coat nut, provides improved cutting performance and extends...

Read More »

Precision Machining Solutions with Over 25 Years of Experience

Quality, customer service, and unbeatable value are the hallmarks of Hogge Precision. Since 1989 we have built a reputation as the go-to precision machining source, servicing many demanding industries. For CNC machining and screw machining, there are few manufacturers that can match our capabilities and expertise. See our video to learn more.

Read More »