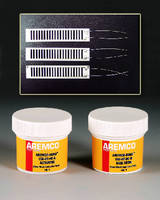

Silver-Filled Epoxy Adhesive suits applications up to 480-

Formulated using high purity silver flake, Aremco-Bond™ 556-HTHC is used for microelectronic chip bonding, semiconductor die-attach, hybrid packaging, and other electrical/electronic assembly applications. Two-part, electrically and thermally conductive adhesive exhibits low volume resistivity of less than 0.0001 Ω-cm at room temperature and thermal conductivity of 2.2 W/m-Ã-

Read More »

Epoxy Adhesive suits microelectronic assembly applications.

Designed to cure rapidly when exposed to high-intensity UV light, 535-10M-45 Epoxy Adhesive contains secondary thermal cure initiator that cures as low as 90Ã-

Read More »Multi-Purpose Repair Epoxy offers syringe-style packaging.

To use Miracle Bond Formula in syringe style package, user twists off cap and presses plunger to dispense resin and hardener until both white and black materials flow evenly. Once dispensed onto flat disposable surface and mixed,Ã- epoxy is ready for application. Adhesive system bonds concrete, brick, wood, stone, ceramics, fiberglass, metal, and some plastics. With non-sag properties,...

Read More »Low-Viscosity Epoxy Adhesives offer fast set times.

Setting in 5, 20, and 46 min, respectively, Quick-Set Trio (10-3005, 10-3020, and 10-3046) cure at room temperature. Clear and solvent-free products are suited for bonding plated metals, pewter, glass, wood, ceramic, felt, cement, gem stones, rubbers, plastics, and more. Offered in TriggerBond dual barrel cartridge system or bulk packaging, products meet UL94 HB requirements; resist effects of...

Read More »

Selecting the Right Materials for Your Metal Stamping Project

Learn about metals and their characteristics to help you choose the right option for your unique application.

Read More »

Low Thermal Expansion Epoxy passes NASA low outgassing tests.

Formulated with blend of polymeric and inorganic materials, 100% reactive EP30LTE-LO is used for bonding, sealing, casting, and coating applications. This 2-component epoxy exhibits dimensional stability and is serviceable over -60 to +250Ã-

Read More »

Flexible Epoxy withstands cryogenic conditions.

Serviceable over wide range of 4 K to 250Ã-

Read More »

Epoxy Adhesive encapsulates sensors in harsh environments.

Combining quartz filler and amine compound, Supreme 45HTQ is suited for bonding and encapsulating transducers, gauges, actuators, and sensors in harsh environments. Epoxy adhesive features tensile strength exceeding 8,500 psi and compressive strength greater than 20,000 psi. Resistant to chemicals, acids, oils, water, and steam, product can withstand long term exposure to 400-500Ã-

Read More »

Heat Resistant Epoxy Adhesive provides high strength bonds.

Withstanding long-term exposure to wide temperature ranges between -100 and +500Ã-

Read More »

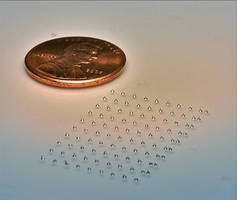

Two-Component Epoxy Adhesives are electrically conductive.

Type 118-15, 123-39, 124-08, and 125-18 are 100% solids silver-filled epoxy systems designed for attachment of electronic components. Featuring 1:1 mix ratio by weight, RoHS-compliant products are fast curing, resistant to thermal shock, and cure in temperatures as low as 80Ã-

Read More »

Metal Bonding Epoxy offers optimal shear, peel strengths.

Formulated for service from -73Ã-

Read More »

Triad's Next-Gen Power Supplies Offer Increased Reliability and Reduced Noise Performance

Triad Magnetics, an established leader in power supply design and manufacturing, is proud to announce their next generation WAU AC and WDU DC Series of power supplies. These linear wall plug-ins offer minimum noise performance without sacrificing reliability or life. See our video to learn more.

Read More »