Two-Component Epoxy Adhesives are electrically conductive.

Press Release Summary:

Type 118-15, 123-39, 124-08, and 125-18 are 100% solids silver-filled epoxy systems designed for attachment of electronic components. Featuring 1:1 mix ratio by weight, RoHS-compliant products are fast curing, resistant to thermal shock, and cure in temperatures as low as 80°C. They are dispensible via syringe or high-speed jet dispensing systems in dots or lines as narrow as 1-3 mils. Each type exhibits other specific characteristics adventageous for specific applications.

Original Press Release:

Introducing Electrically Conductive Epoxy Family of Adhesives

Creative Materials, Inc., introduces superior two-component conductive epoxy adhesives which are easy to use and offer excellent conductivity and bond strength. Part of our family of custom-formulated electrically conductive adhesives, this group of epoxies all possess the same excellent electrical properties and mechanical reliability. Each product in this series varies in its degree of flexibility and rheology to match the requirements of the end-use application. In addition, these products are highly effective and have a very strong track record in a wide variety of applications.

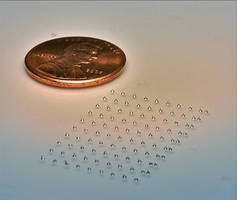

Tyngsboro, MA - Creative Materials introduces our family of electrically conductive epoxy adhesives: 118-15, 123-39, 124-08, and 125-18. These products are 100% solids silver-filled epoxy systems, designed for attachment of electronic components. They have an easy one-to-one mix ratio by weight, are fast-curing, have a long potlife, and are resistant to thermal shock. With excellent rheological properties, these products are dispensible via syringe or using high-speed jet dispensing systems, allowing dispensing in dots or lines as narrow as 1 to 3 mils. In addition, they have a long shelf life in the two-component system, have low cure temperatures (as low as 80°C), are RoHS compliant, and have low ionics. These products are proven performers for electrical component attachment in a wide range of application areas, including solar assembly, medical device and automotive manufacture, electronics and components production. Applications include mounting of LEDs, chip attachment, solar cell assembly, metal to glass bonding, attachment of leads, and lid attachment.

The products in this epoxy family share many of the same characteristics, each featuring some key advantages:

Product number: Special characteristics:

118-15A/B, 118-15C Fast curing with excellent conductivity

123-39A/B, 123-39C Stencilable, with higher viscosity and bond strength

124-08A/B, 124-08C Greater thermal shock resistance and flexibility

124-08LVA/B, 124-08LVC Lower viscosity for jet dispensing systems

125-18A/B, 125-18C Increased bond strength

All are available as two-component (A/B) systems or as single-component precatalyzed (C) products. For further details, please refer to product data sheets: www.creativematerials.com/datasheets.html.

Creative Materials, Inc., is a leading manufacturer of electrically conductive inks, coatings, and adhesives. Products from Creative Materials are used in electronic components for computers, keyboards, cell phones, solar collectors, automobiles and aircraft, for medical electrodes, medical instruments, and heating equipment. Creative Materials is ISO 9001 certified, with an extensive product line that includes more than 1,000 products. The company is renowned for creating custom formulations that are used in a wide variety of global applications, providing cost-effective design solutions for demanding production requirements. With over 80 years of experience in the adhesives, ink and coating industry, our staff combines technical expertise with nimble production capabilities, enabling us to reduce time-to-market for new product applications.

Our products are manufactured to order, with typical lead times of two or more weeks. Pricing is available upon request. For more information about these and other products, please visit our website at www.creativematerials.com, or contact us at info@creativematerials.com.