Grinding Wheels feature porous surface that resists gumming.

Superabrasive vitrified diamond and CBN grinding wheels use KP Bonding Technology to improve performance. Bonding process uses hollow glass spheres as filler material to provide additional strength to bond post, creating porous surface that resists loading and burning. Form-holding capability extends interval between dressing cycles. KP bonded superabrasives can be used for creep feed grinding,...

Read More »Grinding Wheel uses patented bonding to improve part quality.

Muscle Wheel features impregnated resin to reinforce vitrified bond bridge, creating flexible bond that acts as shock absorber during grinding operations. Resin impregnation extends wheel life up to 70 % longer than traditional vitrified CBN wheels, and extends time between dressing cycles. Porosity of wheel improves thermal stability for consistent grinding. Grinding applications include...

Read More »

Grinding Wheels do not soften in water-based coolant..

Neptune(TM) Disc Grinding Wheels utilize X10 technology(TM) to prevent their resin bond from softening in water-based coolant applications. Available in 3 resin bond systems suited to double disc grinding applications, discs include Neptune SD (soft disc), MD (medium disc), and HD (hard disc). Neptune disc wheels are available up to P grade in sizes from 8 to 42 in. and grit sizes from 36 to 120.

Read More »

Grinding Wheel makes it easy on operator.

Type 29 Z-Plus weighs half of typical 4 1/2 in. grinding wheel, thus increasing operator's control and comfort while decreasing fatigue, particularly with small grinders used in tight spaces and at odd angles. Wheel's slightly concave profile lessens grinder's angle of attack, also reducing operator fatigue. Wheel has aluminum oxide abrasive, making it suited for blending and surface weld removal...

Read More »

What You Need to Know About Barrier Technology for Your Food Package

Learn about the Benefits of Barrier Technology

Read More »

Wheels handle demanding loads in shop or warehouse.

Stellana rubber, nylon, and polyurethane wheels, for internal transport equipment, are wear resistant and resist variety of chemicals. Rubber wheels include non-marking rubber and withstand high temperatures. Loads up to 1,102 lbs can be accommodated. Self-lubricating Nylon wheels feature impact resistance and handle loads up to 3,968 lbs. Polyurethane wheels have nylon cores bonded to...

Read More »

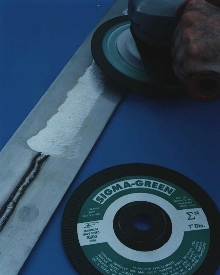

Grinding Wheels quickly remove heavy welds.

Sigma Green Premium Grinding Wheels have zirconia/ceramic grain. Designed for right-angle grinders, wheels come in 4, 4 1/2, 5, and 7 in. diameters, and are available with 5/8-11 throw-away adapters. Wheels cut up to 50% faster than aluminum oxide on 316 stainless steel, and run 20% cooler. Eliminating discoloration and warping of stainless steel and highly alloyed materials, typical applications...

Read More »

Cutting Wheel offers design for extended life.

Slicer Plus has 2 layers of fiberglass to stiffen wheel and ensure accuracy throughout cut. Wheel has ceramic-coated, abrasive-grain formulation and measures .045 in. thick. Slicer Plus cut-off wheel is available for 4 1/2 and 6 in. capacity, right-angle grinders. It is suitable for use on stainless steel, high-carbon steel, and high-tensile strength alloys, as well as cutting partially embedded...

Read More »

Measuring Wheel Hand Grip reduces operator strain.

Ergonomic, pistol-styled handgrip reduces wrist fatigue and provides wheel control in rough terrain or windy conditions. Design includes reduced-wear, clamp-lock mechanism for telescoping aluminum handle that permits handle to extend and retract in same relative position. Handle design is available on mechanical measuring wheels 10 in. or larger in diameter, which includes Series 31, 45, 60, and...

Read More »

Abrasive Points produce highly polished finish.

Unitized Megabrite(TM) Mounted Points provide smooth, chatter-free grinding while maintaining part geometry. Points can be used for light deburring, cleaning, finishing, and polishing machined and cast parts. Made of nonwoven, synthetic-fiber material, impregnated with aluminum oxide or silicon carbide abrasives, conformable points constantly reveal fresh abrasives as they work. Points are...

Read More »

Grinding Wheels are continually sharpened.

CIMFORM(R) MSB has abrasives that micro-fracture during use, creating new grinding surface, and thus constantly sharpening themselves. They are suitable for centerless, center-type, micro-centric, surface, surface/creepfeed, internal, tool manufacturing, and tool cutter applications. MILSPEX(R) educational software tool familiarizes user with grinding technology and processes. DATA PRIME(TM)...

Read More »

Precision Machined Parts for High Tech Applications

For precision and value that sets the standard for quality and craftsmanship, EGS Production Machining is the source for precision and value. Our extensive capabilities and dedication to customer service allow us to deliver the optimal manufacturing solution. See our video to learn more.

Read More »