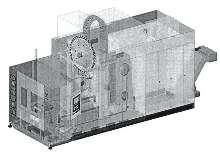

Horizontal Machining Center offers symmetrical design.

Offered in 800 mm size, Mega Series HPC-800HP processes parts up to 51.2 in. dia and 59 in. high with X, Y, Z travels of 57.0 x 4.3. x 49.8 in. Tool-delivery system offers 0.9 sec tool-to-tool interchange and tool queueing. Machine includes dual-ballscrew support on all axes, caged-ball linear-motion guides, and absolute-axis feedback. It maintains X, Y, Z positioning accuracy of Ã-

Read More »

Vertical Machining Centers are offered in seven models.

With trunnion style table system that provides A and C axes, 5-axis model 5ax 400 has 32 x 24 x 20 in. envelope; 1,700 ipm feed rate; and 25 hp, 24,000 rpm spindle. Max load is 440 lb. Bridge-type, high-speed HSC 500 has 20 x 16 x 16 in. X, Y, Z envelope; linear scales on all axes; and 12 hp, 40,000 rpm spindle. Max load is 660 lb. Other models include C-frame and large bridge-types, all with...

Read More »Vertical Machining Centers produce fuel cell mold plates.

V-Series Machining Centers can achieve depth accuracy of Ã-

Read More »

Horizontal Machining Center serves automotive industry.

With 3 liquid-cooled, 15,000 rpm spindles mounted vertically in traveling column configuration, 5-axis Model EA 2600-3 incorporates carousel-style, automatic tool changer and Indramat MTC-200 control system. Column has 24.80 in. Z-axis stroke and travels on 102.36 in. X-axis bed. B-axis rotary table provides one rotary axis, while second rotary axis is supplied by 3 A-axis NC rotary tables...

Read More »Are Starrco Modular Systems Right for Your Application?

Prefabricated construction is a type of construction method that involves manufacturing building components off-site or in a controlled environment

Read More »

Machining Center delivers 5-axis simultaneous machining.

Model UCP 1150 can be switched from vertical to horizontal machining process in 1.7 sec. Milling head with integrated motor spindle allows for spindle rotation up to 135Ã-

Read More »

Multi-Axis Laser System offers 2D and 3D cutting.

Available with 2,500, 3,000, or 4,000 W CO2 laser resonator, DOMINO cuts flat or shaped parts and performs bevel cutting. Cantilever designed 5-axis system has X-Y-Z working capacity of 120 x 60 x 15 in. Laser head also does 2 rotations: 360Ã-

Read More »

Machining Center offers feed rates to 120 m/min..

Model XHC 341 68.5 in. wide horizontal machining center employs linear motor drive technology in all feed axes and rotary direct drives in B-axis and main spindle. Equipped for wet and dry machining, unit offers 800 mm X-Y-Z axis travels and 630 mm dia rotary table. Product, with 16,000 rpm spindle, achieves 4.6 sec chip-to-chip time for dial magazine and 2.7 sec for rack type magazine. Machine...

Read More »

Horizontal Machining Center offers aerospace productivity.

Model A99E-CD utilizes Continuous Dress creep feed grinding technology, and can mill, bore, drill, tap and turn, as well as grind. It removes metal at up to 11 in.Ã-³/min on nickel-based alloys. Milling is at 12,000 rpm on spindle with 4 in. extension, which includes 8,000 rpm continuous dress spindle and 13.8 in. vertical spindle travel path. With X, Y and Z axis travels of 49 x 31 x 49 in.,...

Read More »

CNC Machine combines turning, drilling, milling, and grinding.

Hardpoint 300 can be configured with up to 4 main spindles and variety of tooling combinations, depending on user needs. Number of axes is variable, with up to 10 possible. Machine offers fully automatic, synchronous complete cutting of complex workpiece geometries up to a diameter of 3 x 3 in. It can incorporate internal gantry loader to save floor space. External loaders are available, as well...

Read More »Machining Center machines parts up to 20 mm in diameter.

Equipped with integrated bar feeder, MultiDECO 20/8b has 8 spindles and is available in 2 x 4 configuration. Unit can act as traditional 8 spindle machine or as two 4-spindle machines to produce 2 separate parts simultaneously. Product is offered with TB-DECO software and PNC control. As 8-spindle machine, unit can produce complex parts featuring cross milling/drilling with 23 simultaneous axes,...

Read More »

Precision Machined Parts for High Tech Applications

For precision and value that sets the standard for quality and craftsmanship, EGS Production Machining is the source for precision and value. Our extensive capabilities and dedication to customer service allow us to deliver the optimal manufacturing solution. See our video to learn more.

Read More »