Machining Center offers feed rates to 120 m/min..

Share:

Press Release Summary:

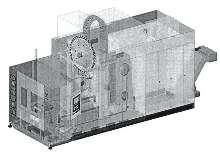

Model XHC 341 68.5 in. wide horizontal machining center employs linear motor drive technology in all feed axes and rotary direct drives in B-axis and main spindle. Equipped for wet and dry machining, unit offers 800 mm X-Y-Z axis travels and 630 mm dia rotary table. Product, with 16,000 rpm spindle, achieves 4.6 sec chip-to-chip time for dial magazine and 2.7 sec for rack type magazine. Machine is offered with integrated broken tool detector.

Original Press Release:

Ex-Cell-O's New XHC 341 High-Speed Machining Center Meets Demands for Efficiency, Accuracy and Flexibility

Sterling Heights, Michigan, September 11, 2003 - EX-CELL-O Machine Tools, Inc., an IWKA Company, has introduced its next-generation XHC 341 high-speed horizontal machining center, a companion to the company's popular 630 mm-size XHC 241 model. With 800 mm X-Y-Z axis travels and 630 mm diameter rotary table, the new XHC 341 is ideally suited for the machining of larger parts as well as for processes requiring multiple clampings. The XHC 341 offers 120 m/min feed rates in X, Y and Z axes; a 16,000 rpm spindle; a 4.6 sec chip-to-chip time for the dial magazine and 2.7 sec for the rack type magazine.

More compact and economical to use than earlier models, the XHC 341 is fully equipped for wet and dry machining, using 50% less coolant and achieving optimum chip disposal in dry and minimum quantity lube (MQL) applications. And, with a maximum width of 68.5 in., it uses only 60% of the floorspace of previous models.

The XHC 341's axis construction and modern linear motor drive technology in all feed axes, as well as rotary direct drives in the B-axis and main spindle, provide exceptional machining accuracy and flexibility. Its axis structure, with a traversable table in Z-direction, enables the machining of deep bores as well as high-precision machining. High accuracies are also achieved with EX-CELL-O's optional compensation-spindle that uses standard tools as well as controlled adjustable tools with an automatic tool changer.

The XHC 341 features built-in interfaces for expandable modules, ensuring easy adaptability to future changes in production needs. It can be applied as a stand-alone machine or as part of a cellular system.

Additional features of EX-CELL-O's XHC 341 include a space-saving rack type magazine for up to 100 tools with an integrated broken tool detector; a large lift gate for easy front loading; as well as an optional linear overhead gantry for loading from above and optional pallet changer accommodating 630 mm x 630 mm pallets.

Complete specifications and information on the XHC 341 high-speed machining center can be obtained by contacting EX-CELL-O Machine Tools, Inc., 6015 Center Drive, Sterling Heights, MI 48312-2667; phone (586) 939-1330; ex-cell-o.com.