Manufacturing Cell cuts aluminum, cast iron, and steel.

Module-Mation(TM) 3-Axis Manufacturing Cell uses reconfigurable elements including spindle, column position, way style, and compound X-Z or Z-Y. Module parameters include 500 mm Z-axis, 400 mm X-axis, and 400 mm Y-axis. Traverse rate is 950 ipm, acceleration rate is 80 in./secÃ-², and thrust is 3,000 psi. Module accepts 40 or 50 Milling Taper or HSK 63 tooling. Motorized spindle, belt-driven...

Read More »

Vertical Machining Center uses linear motor technology.

Model VL 50 offers speed and motion control necessary to perform high-speed point milling in multi-axis contouring applications. Linear technology provides geometric and positioning accuracies, while low-heat, counteracting, permanent magnet linear motors eliminate mechanical backlash, vibration, and noise. Product has X, Y, Z work envelope of 16 x 12 x 8 in. and offers traverse and cutting feed...

Read More »

Machining Center offers full spindle power from 315-6,000 rpm

Model VM560 features 20/25 hp geared head spindle that delivers 6,000 rpm with 415 lb-ft torque. It includes 1,000 psi spindle thru coolant system, and totally enclosed splash guard. All axes have 3 gibs for long life and easy maintenance. CAT 50/30 tool magazine offers 2.0 sec high speed ATC. Fanuc 18MB control features 160M memory, custom macro B with 600 variables, tool life management, and...

Read More »

Machining Center offers automatic attachment-changing option.

Bridge-type, 5-axis Series MP-5F Die and Mold Machining Center provides universal workpiece machining using combination of swiveling head and motor spindle with switchable planetary gearing. Swiveling action makes 2 axes possible using A- and C-axis or B- and C-axis milling heads. Axes can alternatively be used as NC axes, making rough milling and high-speed cutting possible in one setting. Three...

Read More »

Choosing the Right Material for Your Project

When choosing an appropriate metal material, the range of options is so broad that selecting the correct material for your unique application can be challenging. Different metals have characteristics that can affect weldability, ductility, and formability. Our new eBook outlines the unique properties and applications of popular metals including: Stainless Steel Brass Aluminum Copper Titanium

Read More »

Machining Center offers max spindle speed of 12,000 rpm.

Vertical Center (VC) Nexus 510C features high-speed rapid traverse rate of 1417 ipm at 0.5 G acceleration and 2.9 sec chip-to-chip time. Spindle is driven by 25 hp motor. Machining area provides X-axis travel of 41.3 in., Y-axis range of 20 in., and Z-axis travel of 20 in. Table size is 51.18 x 21.65 in. with load capacity of 2640 lb. Tool magazine stores up to 30 tools of 40 taper. Tool-to-tool...

Read More »

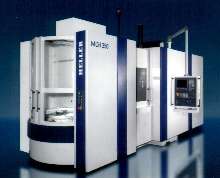

HMC provides small to medium production batch machining.

Model MCH 250 offers working range of 800 x 800 x 800 mm. It includes 43 kw spindle drive, capable of 45-6,000 rpm and 955 Nm torque. Machine moves at 50,000 mm/s rapid traverse with 4 m/secÃ-² acceleration. Pallets are changed within 12 sec, permitting simultaneous part loading and machining. Rotary indexing table includes pin-type pallet alignment for 0.1 mm repeatability. Tool changer...

Read More »

Machining Center provides 5-axis machining.

Model MPF-10 bridge-type machining center provides both A-axis head swivel and C-axis table rotation. Features include head with 230 mm dia snout, TOSNUC 888.2 CNC system, and gearless, direct-drive spindle system. Spindle utilizes motor of 8000 min-1 and 30/37 kW with stepless speed changing system. Pre-loaded linear roller guides support X-, Y-, and Z-axes, while A- and C-axis indexing have...

Read More »

Vertical Machining Center has 33 x 14 in. work surface.

With work envelope of 22 x 16 x 20 in., model D 560 offers rapid traverse rates of 984 ipm for X and Y axes and 787 ipm for Z axis. Machine includes automatic tool changer with bi-directional selection mode, 22-tool capacity, and 5.5 sec station-to-station index time. Additional offerings include 15 hp GE AC spindle motor with infinitely variable high-speed drive from 7-7,500 rpm, automated...

Read More »

Machining Center handles turbine-blade cooling holes.

Model EDGE2S-5X, with sinker EDM technology and single tungsten-carbide electrode, uses electrode rotation and oil-based dielectric fluid. Offerings include 16-station automatic electrode changer, automatic pipe electrode guide, and MR rotating head, capable of Z-axis high-speed pulse machining at 396 ipm. Fixed table eliminates dielectric weight shift during machining, while rotary table can...

Read More »

Machining Center produces mid-sized aerospace components.

Model MAG3 Aerospace Machining Center provides 5-axis horizontal machining. With 9.843 ft X-travel selection, it is equipped with 30,000 rpm, 80 hp, core-cooled spindle. Unit is designed with C-axis behind A-axis rotary head, allowing tool to orient itself toward any position within hemisphere. A-axis allows Ã-

Read More »

Come Alive Organics' Premium Organic Agave Provides a Healthier Choice

Come Alive Organics distributes all-natural, proprietary flavored agave for the food and beverage industry while helping children across the globe. Learn more about our agave products and our one sweet cause in this video and two-page PDF.

Read More »