Micromachining Center manufactures precise, detailed parts.

Constructed on 10 in. granite base, vertically-oriented Hyper2J weighs 11,020 lb and incorporates finished integral guideways. Each axis, capable of submicrometer movement, achieves 472 ipm feedrate while eliminating effects of heat generated by servo motors and ballscrews. With XYZ travel of 7.87 x 5.9 x 5.9 in., center handles up to 88 lb workpiece on 11.8 x 7.87 in. work table and delivers...

Read More »Horizontal Machining Center produces aircraft engine parts.

Model A66E-5XD 5-axis machine achieves 0.9-1.1 sec tool-to-tool time and 2.9 sec chip-to-chip time. Single casting of B and C axes eliminates tool interference and enhances chip removal. Machine incorporates 40-taper, 14,000 rpm spindle and chain-type, 40-tool magazine. It has X-, Y-, and Z-axis travels of 28.7 x 28.7 x 31.5 in. and work zone of 27.6 in. dia x 10.6 in. height. It handles up to...

Read More »Vertical Machining Center offers multi-face accessibility.

Model V33-5XB provides 5-axis simultaneous milling solution for intricate 3D shapes in die/mold applications. Tilt-trunion table, with combined B and C axes, has 7.87 in. dia faceplate, capable of handling 66 lb workpiece with dimensions of 9.85 in. dia x 5.32 in. tall. Features include respective X-, Y-, and Z-axes travel of 23.6 x 12.7 x 13.7 in.; traverse rates of 787 ipm; 20 hp, 20,000 rpm...

Read More »Horizontal Machining Center suits transfer line machining.

Offering tool-to-tool time of 1.1 sec and chip-to-chip time of 1.2 sec, Model J4M features XYZ axis of 19.69 x 22.05 x 19.69 in., rapid traverse of 2,362 ipm, and feedrate of 1,969 ipm. It includes 16,000 rpm spindle and HSK-63A tooling interface. Standard 15-tool ATC handles tools up to 12.21 in. in length and 4.33 in. in diameter. Positioning accuracy is Ã-

Read More »

There's More to Plating than You Zinc!

To find out more about the seven demands you should make of your zinc plater, download now.

Read More »Vertical Machining Centers use geometric intelligence.

V-Series vertical machining centers incorporate SGI.4 geometric intelligence technology, which enables processing of long, complex mold programs. On-the-fly, 3D compensation allows machining centers to track precisely programmed toolpath on mold contours and complex geometries 5 times faster than feed rates of conventional machines. System anticipates servo lag or following error for upcoming...

Read More »

Vertical Machining Centers offer high-speed CNC options.

Digital Model 104/D CNC, with 850 MHz Pentium III processor, uses menu system to capture part, tool, and position data. Existing part programs can be run without editing. Control offers integrated 10BaseT/100 Ethernet, 2 Gb data storage capacity, and 15 in. LCD display. GE Fanuc Series 18i MB5, with 5-axis capability, provides straightforward operator interface and interactive screens. Siemens...

Read More »

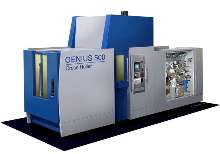

CNC Machine targets automotive parts manufacturers.

Single-spindle GENIUS 500 combines speed of linear motors along X and Y axes with force of ball screw along Z axis. It features XYZ travels of 630 x 630 x 1,000 mm, 500 x 500 mm pallet with 800 mm clearance diameter, and 16,000 rpm spindle with output of 25 hp/37.5 kW. Acceleration forces are resolved in vertical plane directly through walls of machine base, into machine foundations, enabling...

Read More »

Machining Center suits high-speed milling and contouring.

Matsuura H.Plus-405 has max work envelope of 25.59 dia x 29.50 in., max load capacity of 881 lb, and 31-station ATC. Machine offers feed rates and rapid traverses to 1968 ipm in all axes, and accelerations to 1 G. Its 12,000 rpm BT40 taper spindle delivers high torque at low speeds and 30 hp at high speeds. High-speed 1Ã-

Read More »

Horizontal Machining Center includes pallet automation.

Horizontal Machining Center, Model FA450-III can be paired with high-speed rail guided vehicle and pallet storage system to form complete metal-cutting cell. Three-level stocker system allows unmanned machine loading and lights-out production. Due to modular design and virtually unlimited capacity, additional machines, loading stations, and up to 120 pallets can be added without interrupting...

Read More »

Five-Axis Machine meets automated production demands.

High-speed Model UCP 600 Vario features modular tool changer that can hold 100-220 tools. With 7-position pallet changing system, workpieces with surface area up to 13 x 13 in., height of 14 in., and max weight of 176 lb can be automatically changed and simultaneously machined. Available with 12,000, 20,000, or 42,000 spindle options, machining center includes rotary/tilt table that swivels...

Read More »

Cut and Bevel Pipe up to 63" Diameter with a Single Lightweight, Portable Machine

CS Unitec is a leader in power tools designed for industrial applications, with products that set the standard for robust performance and industry-leading reliability. Adding to our long list of innovation is a new line of pipe cutting machines. For cutting and beveling pipe up to 2" in thickness and diameters from 12" to 63", no other cutting system comes close. See our video to learn more.

Read More »