Metal Adhesive requires no primers.

Metal Welder II 2-part, 10:1 methacrylate adhesive bonds metal to other metals or to dissimilar substrates. Mixed and dispensed from manual or pneumatic dispensers with static mixing nozzles, it attains functional cure in 2-4 hours at room temperature. Load-bearing bonds withstand service temperatures from -40 to 250Ã-

Read More »

Hot-Melt Adhesive System has large-volume reservoir.

Upright, free-standing 3910 Series Thermopulse Hot Melt Unit includes 10 gal (80 lb) melt-on-demand reservoir and positive-displacement, dc-motor-driven gear pump. Suited for use with up to 4 automatic or handgun Electromatic Applicator Heads and hoses, unit holds constant pressure to within Ã-

Read More »

Polyurethane Adhesive suits aerospace/military applications.

NASA outgassing approved Tra-Bond 240-2 offers various cure schedules, including one at room temperature. Flexible polyurethane is suited for aerospace and military applications where substrates consist of polyurethane or other hard-to-bond-to materials. With work life of 2 hr at room temperature, product has a shelf life of 6 months when stored at -40Ã-

Read More »

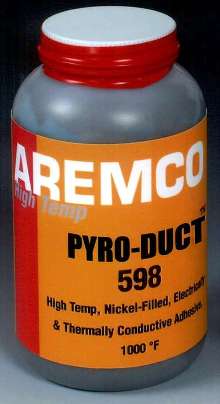

Electronics Adhesive withstands temperatures to 1,000-

Filled with nickel-flake particles, Pyro-Duct(TM) 598 is silicate bonded and electrically conductive. It provides volume resistivity of .005 ohm-cm and thermal conductivity of 17.9 Btu-in/hr-ftÃ-²-Ã-

Read More »

A Comparative Guide to Sweeteners in the Food and Beverage Industry

To learn more about the benefits of agave over other sweeteners, and how Come Alive Organics can help source your needs, download now.

Read More »Adhesive Film suits direct skin application.

BioflexÃ-® Rx914P breathable, co-polyester film is single coated with medical grade acrylic, pressure-sensitive adhesive. Adhesive carries Device Master File Number with Bureau of Medical Devices and is supplied with 60 lb. kraft release liner. It adheres well to skin, yet removes cleanly without causing skin trauma, making it suitable for wound care, ostomy care, IV dressing, and medical...

Read More »Flexible Adhesive suits assemblies subject to stress.

With tensile elongation of 130-140%, Flex Welder(TM) structural methacrylate adhesive fills gaps up to 3/8 in. and bonds plastics, composites, and metals in applications involving flexing, shock, or vibration. Room-temperature-cure adhesive provides load-bearing bonds that withstand impact, weathering, humidity, and temperature variations up to 250Ã-

Read More »

Compound prevents weeping on crimp seals of filters.

PermabondÃ-® HH040 one-part, high-viscosity, anaerobic retaining compound cures only when in contact with metal parts and oxygen is excluded. Compound fills air space between parts and unitizes and retains male and female parts. Green compound cures at room temperature to crosslinked thermoset plastic. Cure can be accelerated by heat. It has viscosity of 5000 cP and shelf life of 12 months...

Read More »

Rubber-Based Adhesive is suited for automotive assembly.

With 12-point liner and polyester carrier, MACbondÃ-® IB-1185 performs general-purpose bonding applications, providing dimensional stability and die-cutting properties suited for automotive manufacturing. Product offers high-tack properties suited for bonding applications such as gasketing, sound dampening, and dust sealing.

Read More »

Adhesive continues to cure after exposure to UV light.

Type LL499 dual cure adhesive is used for bonding, sealing, and potting metal and plastic components. It cures when exposed to UV light, and will continue to cure by exposure to ambient or surface moisture. Translucent, light blue product has viscosity of 3,100 cP and shelf life of 3 months when stored at 77Ã-

Read More »Adhesive Transfer Film adheres to skin without irritation.

BioflexÃ-® Rx230U medical grade, unsupported acrylic adhesive carries Device Master File Number with Bureau of Medical Devices. It is supplied on 60# white densified kraft release liner and can be laminated to variety of substrates. Adhesive film provides UV and humidity resistance, and is suitable for use on medical devices that will adhere to human skin such as wound care and ostomy...

Read More »

Basalt America Announces Stronger, Lighter, and Corrosion-Free FRP's (Fiber Reinforced Polymers)

Fiber Reinforced Polymers (FRP), represents a truly groundbreaking advancement in structural reinforcement. Lightweight, strong, and green, they are changing the way the construction industry thinks about rebar. Unlike steel, FRPs don't rust and are far stronger than standard rebar. To learn why Fiber Reinforced Polymers are poised to change the way the world builds, see our video.

Read More »