Master Bond, Inc.

Hackensack, NJ 07601-3950

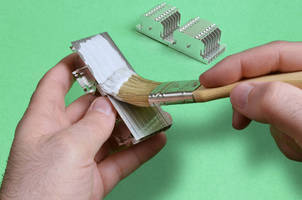

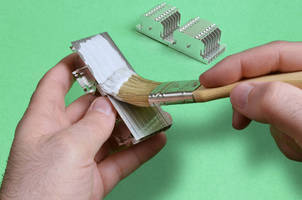

Non-Drip, One Component Silicone Offers High Temperature Resistance, Thermal Conductivity and Electrical Isolation

Non-Drip, One Component Silicone Offers High Temperature Resistance, Thermal Conductivity and Electrical Isolation Placing an emphasis on convenient handling, Master Bond MasterSil 705TC features a paste consistency that doesn't require mixing. This single component system sets up in 7 minutes and has a non-corrosive cure at room temperature when exposed to atmospheric humidity. Suitable for a...

Read More »

Low Thermal Expansion Epoxy passes NASA low outgassing tests.

Formulated with blend of polymeric and inorganic materials, 100% reactive EP30LTE-LO is used for bonding, sealing, casting, and coating applications. This 2-component epoxy exhibits dimensional stability and is serviceable over -60 to +250Ã-

Read More »

Flexible Epoxy withstands cryogenic conditions.

Serviceable over wide range of 4 K to 250Ã-

Read More »

Epoxy Adhesive encapsulates sensors in harsh environments.

Combining quartz filler and amine compound, Supreme 45HTQ is suited for bonding and encapsulating transducers, gauges, actuators, and sensors in harsh environments. Epoxy adhesive features tensile strength exceeding 8,500 psi and compressive strength greater than 20,000 psi. Resistant to chemicals, acids, oils, water, and steam, product can withstand long term exposure to 400-500Ã-

Read More »

Heat Resistant Epoxy Adhesive provides high strength bonds.

Withstanding long-term exposure to wide temperature ranges between -100 and +500Ã-

Read More »

Adhesive for Fiberglass Remarkably Resistant to High Temperature

Master Bond fiberglass adhesive EP33 facilitates the reliable bonding of fiberglass to a variety of different substrates. It has been specially designed to overcome CTE mismatch complications. Curing at room temperature, it produces durable, high strength, and tough bonds between fiberglass, wood, metals, vulcanized rubbers and many plastics. The cured fiberglass adhesive composition is an...

Read More »

Metal Bonding Epoxy offers optimal shear, peel strengths.

Formulated for service from -73Ã-

Read More »

Epoxy Adhesive/Sealant meets NASA low outgassing requirements.

Offering optical clarity and chemical resistance, UV10TKLO-2 is not oxygen inhibited and cures rapidly at room temperature when exposed to UV light. Maximum UV absorption takes place in 320-365 nm range. One component, modified epoxy system has volume resistivity of greater than 1014 W cm, dielectric constant of 3.6 at 60 Hz, and service temperature of -60 to 300Ã-

Read More »

Adhesive/Sealant contains no solvents or diluents.

Storage-stable, one component, low viscosity system, EP19HT adhesive/sealant, impregnant, and liner features viscosity of 500-600 cps at 75Ã-

Read More »

A Versatile Aerospace Epoxy Conquers Cryogenic Wind Tunnel

2/26/2009 A uniquely formulated epoxy adhesive has come to the rescue in an extraordinarily difficult cryogenic wind tunnel model bonding application. The state of the art wind tunnel poses a difficult challenge to engineering thermoplastics, not only in terms of the low temperatures and vacuum conditions, but in terms of thermal, thermal cycling and mechanical shear stresses. Cooled to 113Ã-

Read More »Understanding Optical Transmission of Adhesives

Optical transmission is the ability for light to be channeled through a material, and it is measured from 0 to 100% on a wavelength scale of approximately 200 to 3,100 nanometers (nm). This property is essential for a number of applications in the optical and electro-optical industries. Most optically clear epoxies, polysulfides, and silicones offer excellent light transmission across the visible...

Read More »How to Optimize Bond Strength

Proper surface preparation is an essential part of optimizing bond strength. This infographic breaks down the various options ranging from abrasion to chemical etching when it comes to bonding rubbers, metals and plastics. Read More: http://click.skem1.com/click/gj688-awf98y-13mg5462/ Master Bond Website: www.masterbond.com Email: newsletters@masterbond.com Phone:+1 201 343 8983

Read More »Developed for Chip-on-Board Encapsulation Applications, Master Bond Supreme 3HTND-2DM is a Rapid Curing, Toughened, One Part Epoxy System that Can Be Used for Dam-and-Fill

This video demonstrates the process of dispensing the epoxy paste and creating a barrier, or “dam”, which can then be filled by a flowable encapsulant. This thermally conductive compound also meets NASA low outgassing specifications and can withstand 1,000 hours at 85°C/85% RH. Read More (http://click.skem1.com/click/fm07e-ahgtxl-13mg5468/) Updated Electronic Industry Catalog This 36-page...

Read More »White Paper: Silicones Meet the Needs of the Electronics Industry

Silicones offer the ability to maintain their physical properties across a wide range of temperatures while featuring unmatched flexibility. In this white paper, learn what makes silicones different from other organic polymers, and how they are playing a special role in the development of emerging electronic device technology. Electrically Conductive System Has High Flexibility MasterSil 973S-LO...

Read More »Webinar Explains How to Select an Adhesive for Aerospace

Master Bond’s technical experts clear up some of the unique challenges associated with selecting high performance adhesives for aerospace applications in a pre-recorded webinar presented with NASA Tech Briefs. They explain the many parameters to consider, including adhesion, temperature resistance, handling and curing time, among others. This webinar also focuses on different cure mechanisms...

Read More »New Catalog: Adhesives, Sealants & Coatings for the Optical Industry

This 24 page catalog features performance properties on Master Bond’s extensive line of epoxy, silicone and light curing compounds that meet the specific demands of the optical, fiber-optic, electro-optic, display, photonic and biophotonic industries. These products are used for bonding, laminating, sealing, coating, precise positioning, fixturing, mounting and potting/encapsulation. EP30-2LB:...

Read More »Master Bond Introduces New Catalog on Adhesives, Sealants and Coatings for the Aerospace Industry

Master Bond is offering a new, easy to read, 28 page catalog with performance and processing data on its extensive line of epoxies, silicones, UV curing compounds and specialty systems for the aerospace industry. These products ensure reliability in the assembly of aircraft structures, components, interiors and MRO applications. They are widely used for structural bonding, sealing and gap...

Read More »

Non-Drip, One Component Silicone Offers High Temperature Resistance, Thermal Conductivity and Electrical Isolation

Non-Drip, One Component Silicone Offers High Temperature Resistance, Thermal Conductivity and Electrical Isolation Placing an emphasis on convenient handling, Master Bond MasterSil 705TC features a paste consistency that doesn't require mixing. This single component system sets up in 7 minutes and has a non-corrosive cure at room temperature when exposed to atmospheric humidity. Suitable for a...

Read More »Master Bond Introduces New Catalog on Adhesives, Sealants and Coatings for the Electronic Industry

New, easy to read, 32 page catalog offers performance and processing data on Master Bond’s extensive line of epoxy, silicone, polyurethane, silicate based and light curing compounds. These products provide solutions to PCB assembly, die-attach, conformal coating, surface mount, lid sealing, chip and wire bonding applications. Convenient, efficient and reliable packaging options are also...

Read More »

Low Thermal Expansion Epoxy passes NASA low outgassing tests.

Formulated with blend of polymeric and inorganic materials, 100% reactive EP30LTE-LO is used for bonding, sealing, casting, and coating applications. This 2-component epoxy exhibits dimensional stability and is serviceable over -60 to +250Ã-

Read More »