Solder Paste features colored labeling for identification.

SolderPlusÃ-® dispensable solder paste formulations are packaged in 3, 5, 10, 30, and 55 cc syringes with green end caps and green leaf label design for immediate recognition on production floor. Tin/silver, tin/silver/copper, and tin/bismuth alloys have low liquidus temperatures from 217 to 138Ã-

Read More »

Solder Paste remains soft and pliable.

SynTECH(TM) no-clean solder paste is made with synthetic poly adducts and yields reliable solder joints in SMT PC board assemblies. It offers wide process windows with 12 to 18 hr stencil life and 18 to 24 hr tack time. Paste leaves non-conductive, non-corrosive post reflow residue, which acts as protective coating. SynTECH requires no refrigeration. It is suitable for in-circuit testing of fine...

Read More »

Solder Paste joins hard-to-solder materials.

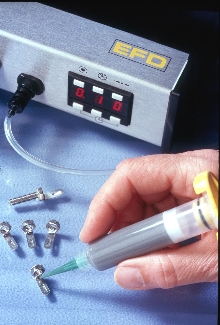

SolderPlus with WS421 flux offers aggressive flux chemistry that provides suitable bonding strength for mechanical assembly applications. Available in lead-free and tin/lead solder paste alloys, it is prepackaged in EFD syringes for precise application with automatic dispensing equipment. Solder paste works successfully on hard-to-solder materials such as stainless steel 304 and 316, Nichrome,...

Read More »Solder Paste eliminates tombstone defects.

LoctiteÃ-® MulticoreÃ-® 63S4 RP15 phased-reflow, no clean solder paste is formulated with 63S4 alloy. 63S4 alloy blends SN63 and SN62, with melting points of 183Ã-

Read More »

Understanding the Design & Construction of Cleanrooms

Cleanrooms find application in a number of industrial operations, including serving as working spaces for sensitive manufacturing, assembly, and both research and medical field applications.

Read More »

Solder Paste produces consistent joints without cleaning.

SolderPlus No Clean solder paste prepackaged alloy/flux blend is formulated for controlled application by automatic dispensing equipment. It provides control and speed in production soldering processes by producing consistent solder deposits without needing to remove flux residue. This tacky paste is suitable for electronic, electromechanical and telecommunications applications.

Read More »

Solder Redefined

Indium Corporation has developed a new twist on traditional solder by developing a composite with a reinforced matrix internal structure. The result is a solder with increased strength and reliability. Check out this video to learn more about the mechanics behind the groundbreaking technology.

Read More »