Colloid Mill is fully adjustable during operation.

Z-Series Sanitary Colloid Mills produces ultra-fine particle size reduction and sub-micron dispersions and emulsions of varying viscosities. Milling head requires no special assembly tools, and rotor/stator gap adjustment, isolated from process area, is fully adjustable during operation. Featuring 316 stainless steel construction with VitonÃ-® O-rings, mill is available with flow rates from...

Read More »

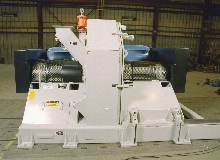

Cage Mill offers 2-4 or 6-row design.

Series H Multi-Cage Mill comes in 4 sizes up to 250 tph. Air cannons are mounted at intake and discharge to help prevent build-up of wet sticky material, while heaters are installed on grinder housing to retard buildup of wet material. Hydraulic ram eliminates gear head motor and rack and pinion used on other cage mills. Selective-crushing, controlled-impact mill sizes minerals, agglomerates,...

Read More »

Knife Mill grinds coated tablets for analysis.

Grindomix GM 200 is able to grind 20 gelatin-coated tablets in a few seconds, providing homogenous sample for analysis. It features feed size of 10-40 mm and produces final fineness down to approximately 0.3 mm. Parameters can be set for reproducible results. Grindomix GM 200 is particularly suitable for grinding larger tablets and plants with high fat or moisture content.

Read More »

Mills are sized for laboratory grinding.

Non-metal MiniCer and MiniPur are part of MiniZETA laboratory-sized equipment line. MiniCer is manufactured with zircon-oxide wetted components, while MiniPur has polyurethane wetted components. Both machines feature adjustable position chamber and are capable of handling batch sizes down to 250 mL, with chamber volume of 150 mL. Optimized for circulation or discrete pass milling, products can...

Read More »

Nylon Washers for Your Automotive Applications

This ebook provides an overview of nylon washers in the automotive industry.

Read More »

Conical Mill provides fine particle size reduction.

MKO 2000 Cone Mill(TM) deagglomerates hard to mill materials such as crystals and pigments. Conical rotor and stator of mixing tool uses spiral-shaped teeth for pre-milling and coarse surface coating for fine milling. Combination provides grinding action of stone mill with fluid dispersing capabilities of colloid mill. Mill eliminates need for multiple passes and expensive preprocessing. Cone...

Read More »

Grinding Mill produces powders as fine as 40 microns.

Ultra Centrifugal Mill ZM 200 incorporates 3-phase Powerdrive with optimally matched frequency converter. Combined with automatic cover closure and dust protection, product is suited for all standard and heavy-duty grinding operations to reduce dry, medium-hard samples to powders as fine as 40 microns. Additional offerings include speed selection of 6,000-18,000 rpm and ability to set parameters...

Read More »

Small-Media Mill requires only 0.9 qt of media volume.

Model QC-150 features QC-Mill(TM) high-circulation design. Rotor creates strong centrifugal and shearing forces inside mill, and combined with fast circulation of slurry, forces result in efficient grinding with narrow particle size distribution. Holding tank has capacity of 3-15 gal. Mill runs to max speed of 2,200 rpm with motor capacity of 7.5 hp. Simple design makes mill easy to clean and...

Read More »

Roll Mills offer fine milling with tightly controlled output.

SUPREME(TM) Roll Mills, available in carbon or stainless steel, employ dual, counter-rotating serrated or grooved rolls that mill, pinch, and crack solids to output range of 13-150 mesh without degrading qualities of feed material. Carbon steel Model 1010M features serrated 10 x 10 in. rolls, variable roll gap, hopper feed regulator, automatic spring overload relief, output enclosure for dust...

Read More »

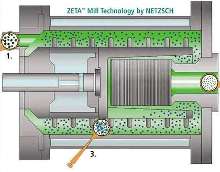

Bead Mills reduce particles to submicron sizes.

Horizontal Agitator Bead Mills grind particles with initial fineness of 1-20 micrometers down to 40-200 nanometers. In enclosed vessel filled with grinding media, agitator shaft activates media, creating shearing and impacting forces. Rotation of agitator imparts energy to surrounding media. Forces either fracture, tear, or crush particulate. Dynamic Cartridge Media Separator retains media in...

Read More »

Ball Mills offer speeds to 650 rpm.

Bench-top planetary ball mills provide continuous operation without cooling down times. Single-station Model PM 100 handles grinding jars from 50-500 ml, while dual-station Model PM 200 accepts jars up to 125 ml. Both include easysafe clamp, balance control, memory for 10 parameter combinations and delayed start, and motor driven lock of cover. Display provides parameter setting and control,...

Read More »

Error Proofing by Design

Sturtevant Richmont's torque tools help customers cut rework and warranty costs while increasing throughput.

Read More »