Cage Mill offers 2-4 or 6-row design.

Press Release Summary:

Series H Multi-Cage Mill comes in 4 sizes up to 250 tph. Air cannons are mounted at intake and discharge to help prevent build-up of wet sticky material, while heaters are installed on grinder housing to retard buildup of wet material. Hydraulic ram eliminates gear head motor and rack and pinion used on other cage mills. Selective-crushing, controlled-impact mill sizes minerals, agglomerates, whole grains, chemicals, and ores to uniform particle size.

Original Press Release:

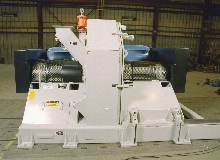

New H Series Cage Mills from Stedman

Aurora, IN - The Stedman H series multi-cage mill is available in 2-4 or 6-row design. Four sizes up to 250 TPH.

The new design features include Air Cannons, Heaters, and Hydraulic Ram.

The Air Cannons are mounted at the intake and discharge to help prevent build-up of wet sticky material, while the heaters are also installed on the grinder housing to retard buildup of wet material. The Hydraulic Ram eliminated the gear head motor and rack & pinion that were used on other Stedman cage mills, now costing less to maintain.

The cage mill is a selective crushing, controlled-impact, multi-cage mill designed for sizing minerals and agglomerates, whole grains, chemical, ores and many other materials. Process wet and sticky materials as well as dry materials into a carefully controlled uniform particle size. Also, available in stainless steel construction. Testing facilities available for proof before purchase.

For more information, contact Stedman, Sales Department, P.O. Box 299, 129 Franklin St., Aurora, IN 47001. Telephone: 800-262-5401 or 812-926-0038 or Fax 812-926-3482. E-mail: prnwpr@stedman-machine.com. Website: www.stedman-machine.com.