Union Process Produces Twin Q-50 Attritors for Food Industry Customer

Akron, Ohio...Union Process, a manufacturer of grinding and dispersing equipment as well as related services for a broad range of industrial applications, has designed and built two Q-50 Circulation Attritor Grinding Mills for a long-standing customer in the food service industry. Although the customer has purchased circulation Attritors from Union Process in the past, these twin Q-50 Attritors...

Read More »

Jet Mill features stainless steel collection module.

Suited for biotechnology and pharmaceutical powder processing applications, 00 Jet-O-Mizer is available with High-YieldÃ-® Collection Module upgrade, which collects 98% of compounds processed during jet milling. Module is self-contained and operates pneumatically using same compressed air or gas that runs jet mill. Capable of processing batches from 1-50 g, collection container comes equipped...

Read More »Union Process Produces SDL-30 Batch Attritor for Grinding Under Liquid Nitrogen

Akron, Ohio. . .Union Process, known globally as a manufacturer of size reduction and dispersing equipment for research and industrial applications, has manufactured a custom model SDL-30 dry grinding batch Attritor for a customer producing desiccants (sorbents) for the food, pharmaceutical, medical/diagnostic and electronics industries. This SDL-30 Attritor has a special cover with a Teflon...

Read More »

Hammer Mill reduces friable and fibrous materials.

Utilizing centrifugal force, Model 141 reduces materials into uniform particle sizes from 20-300 mesh. Shaft, integral hammer discs, disc pins, and hammers are driven by 75 hp motor at 1,800-4,000 rpm, achieving hammer tip speeds from 8,700-19,500 fpm. Particle size is determined by size of screen perforations. In addition to lower 180Ã-

Read More »

Choosing an Optimal Custom Label Printer: 5 Key Factors

Read about the 5 primary key factors you should consider when choosing an optimal label printer for your company.

Read More »

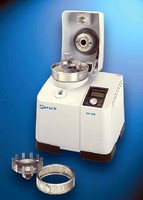

Disk Mill achieves grind sizes of 40-100 microns in seconds.

Featuring 1.5 kW stabilized plane drive, RS 200 Vibratory Disk Mill grinds samples up to 250 ml with max particle feed size of less than 15 mm. Made of chrome steel, tungsten carbide, zirconium oxide, or agate, dust-tight grinding sets are contamination-free and neutral-to-analysis. Mill includes all-digital controls with memory for up to 10 grinding programs, automatic recognition, and speed...

Read More »Attritor suits cryogenic milling of aluminum powders.

Featuring cover with TeflonÃ-® shaft seal for grinding at low temperatures, Model S-50 includes vent port for liquid nitrogen as well as ports for thermocouples. Jacket around exterior of tank maintains full vacuum at temperatures as low as -320Ã-

Read More »

Centrifugal Mill processes without cross contamination.

With high torque motor and cassette principle, Ultra Centrifugal Mill ZM 200 handles hundreds of samples per day without cross contamination. Size reduction takes place by impact and shearing effects between rotor and fixed ring sleeve. Two-step process ensures quick, gentle processing. Mill is suited for applications such as foods and feeds, spices, pharmaceuticals, fertilizers, powder coatings,...

Read More »

Grinders cut and tear flax seeds into fine powder.

Utilizing water-cooled rollers and tooth profile for cutting and tearing flax seed into very fine powder, Model 88 WC Flax Seed Gran-U-Lizer(TM) grinders have capacities from 2,000-4,000 lb/hr, depending on grind size setting. Grinder design eliminates need for screens, thereby eliminating product stickiness and gumming. Larger and smaller versions are also available.

Read More »

Roller Mill features wash down construction.

Equipped with 8 x 50 in. rolls, Frozen Egg Yolk Gran-U-Lizer(TM), Model 900.EY handles products that are breakable. It reduces frozen egg yolk patties to uniform particle size suitable for institutional diced egg product applications, minimizing amount of sifting required.

Read More »Grinder increases particle uniformity and minimizes fines.

Model 1052 SAP Gran-U-Lizer(TM), designed for grinding super absorbent polymers (SAPs), features balance and vibration analysis (BAVA) that senses when product moisture levels elevate beyond tolerable range. While able to sense material elasticity change and notify plant personnel, BAVA can also predict bearing failures before they occur. In addition to grinding SAP materials, product also works...

Read More »

What Can Test Devices Spin for You?

Test Devices helps you ensure the safety and efficiency of your high performance machines with cutting edge spin testing, rotor engineering, and precision balancing capabilities. Check out the video to learn more.

Read More »